Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

What is a Chiller in HVAC? Ever wondered how big buildings stay cool and comfy, even when it’s really hot outside? The answer is a chiller, a key piece of HVAC equipment.

A chiller is a high-tech machine that takes heat out of liquid using special refrigeration cycles. It’s different from regular air conditioners because it cools down big areas like hospitals and factories more efficiently.

In the HVAC world, chillers are vital for keeping things at the right temperature. They move heat from one place to another. This makes spaces and equipment cooler, all thanks to their precise cooling process.

Key Takeaways

- Chillers are specialized HVAC cooling machines that remove heat from liquids

- They use advanced refrigeration cycles for efficient cooling

- Chillers are essential in large commercial and industrial settings

- These systems provide centralized temperature control

- Chillers can cool both spaces and specific equipment

Table of Contents

Understanding HVAC Chiller Systems

Industrial chiller systems are key to keeping places comfortable and controlled. They use advanced cooling technology to manage temperature with great accuracy.

At their heart, these systems use complex heat transfer and refrigeration. They cool and dehumidify air in buildings through chilled water and pipes. This is vital in commercial, industrial, and institutional settings.

Basic Operating Principles

The main steps of how chiller systems work are:

- They absorb heat from inside the building.

- They move heat through refrigerant cycles.

- They release heat outside the building.

- They keep temperature and humidity steady.

Role in Building Climate Control

Hvac mechanical cooling systems are vital for indoor comfort. They help:

- Keep temperature even in big areas.

- Control humidity levels.

- Ensure consistent comfort.

- Protect sensitive equipment and processes.

Common Applications

Industrial chiller systems are used in many areas, including:

- Manufacturing facilities needing precise temperature control.

- Healthcare places with strict environmental needs.

- Data centers dealing with heat from computers.

- Large commercial and office buildings.

Knowing how these systems work shows their importance in today’s buildings and climate control.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopTypes of HVAC Chillers

Choosing the right air conditioning chiller is key for your HVAC system. There are many types available, each designed for different cooling needs in various industries.

Chillers fall into main categories based on how they cool and how they work:

- Air-Cooled Chillers

- Water-Cooled Chillers

- Absorption Chillers

- Specialized Chillers

Air-cooled chillers use outside air to cool the refrigerant. They’re great for small spaces or places with little water. These chillers are compact and can be set up outside with little setup needed.

| Chiller Type | Key Characteristics | Best Application |

|---|---|---|

| Air-Cooled Chillers | Easy installation, lower initial cost | Small commercial buildings |

| Water-Cooled Chillers | Higher efficiency, consistent performance | Large industrial facilities |

| Absorption Chillers | Uses heat for cooling process | Facilities with waste heat |

Water-cooled chillers are more energy-efficient and best for big commercial and industrial places. They use water to cool, giving better temperature control than air-cooled systems.

Special chillers like glycol and centrifugal ones meet specific cooling needs in certain fields. They ensure exact temperature control in important areas.

What is a Chiller in HVAC: Core Components and Functions

Commercial chiller units are key in cooling big spaces and industrial processes. They have complex parts that work together to cool efficiently.

Chillers have many parts that work together to cool spaces. Let’s look at the main parts that make these machines work well.

Compressor System: The Heart of Cooling

The compressor is the main part of the cooling system. It does several important things:

- Pressurizes refrigerant gas

- Makes refrigerant temperature go up

- Moves refrigerant through the system

Condenser Unit: Heat Rejection Mechanism

The condenser is key for cooling systems. It does a few important things:

- Changes high-pressure gas into liquid

- Releases heat outside

- Readies refrigerant for cooling again

Evaporator Assembly: Cold Generation Zone

The evaporator is where cooling happens. It absorbs heat from the area. Key characteristics include:

- Low-pressure liquid refrigerant expansion

- Takes heat from air or water

- Cools the area

Control Systems: Precision Management

Modern chillers have smart control systems. These systems watch and control the cooling process. They make sure everything runs smoothly, uses less energy, and keeps temperatures steady.

Precise engineering turns complex cooling into reliable solutions.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

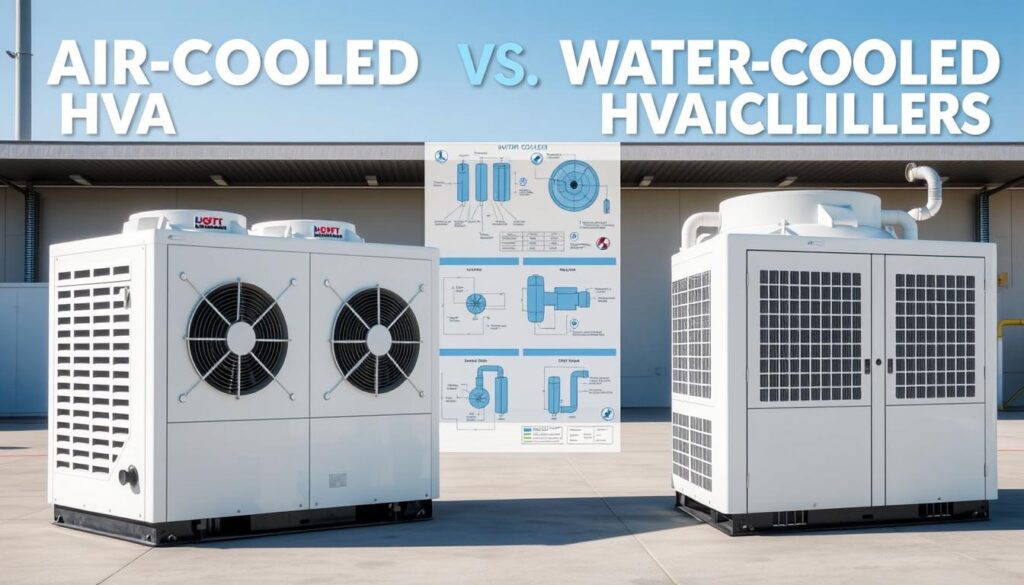

Visit the ShopAir-Cooled vs Water-Cooled Chillers

When choosing hvac cooling equipment, you’ll find two main types: air-cooled and water-cooled chillers. Each has its own benefits for different places and needs.

Water-cooled chillers use a cooling tower to cool the refrigerant. They work best in big commercial and industrial places where steady cooling is key. They offer:

- Higher energy efficiency

- More stable temperature control

- Longer operational lifespan

Air-cooled chillers cool down using the air around them. They’re great for smaller areas or places with little water. Their main advantages are:

- Lower initial installation costs

- Simpler maintenance requirements

- More flexible placement options

Your choice between water-cooled and air-cooled chillers depends on several things:

- Available space

- Climate conditions

- Budget constraints

- Energy efficiency goals

Experts say to check your cooling needs to pick the best hvac cooling equipment for your project.

Industrial and Commercial Applications

Industrial chiller systems are key in many fields. They control temperature for complex processes and protect sensitive equipment. These systems are vital for keeping machines running well in various settings.

Commercial chiller units offer precise cooling for many industries. They are flexible and accurate, making them essential for keeping environments just right.

Manufacturing Facilities

In factories, chiller systems are vital for quality control. They cool:

- Plastic injection and blow molding

- Metalworking and cutting

- Die-casting equipment

- Machine tooling temperature

Healthcare Institutions

Healthcare needs precise chiller units for its equipment. These systems keep temperatures stable for:

- Medical equipment cooling

- Laboratory research

- Pharmaceutical storage and processing

- Surgical suite climate control

Data Centers

Data centers need advanced chillers to avoid overheating. They keep servers running at their best by:

- Preventing thermal stress

- Keeping computational efficiency

- Protecting electronic components

- Lowering energy use

Choosing the right chiller system is key for efficiency and equipment life in these industries.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopChiller Efficiency and Performance Ratings

It’s key to know about chiller efficiency ratings to make your HVAC systems better. Experts and building managers look at important metrics to see how well cooling systems work.

Chiller efficiency is checked through a few main indicators:

- Coefficient of Performance (COP)

- Energy Efficiency Ratio (EER)

- Kilowatts per Refrigeration Ton (kW/RT)

The Coefficient of Performance (COP) shows how much cooling you get for the energy you use. For big chillers, a good COP is between 3.5 and 7.0. The higher it is, the better the chiller works.

| Efficiency Metric | Typical Range | Performance Interpretation |

|---|---|---|

| COP | 3.5 – 7.0 | Higher values indicate better performance |

| kW/RT | 0.5 – 1.2 | Lower values suggest more efficient cooling |

Things that can change chiller efficiency ratings include:

- Ambient temperature conditions

- Current operational load

- Regular maintenance practices

- Equipment age and technological capabilities

Choosing chillers with high efficiency ratings can cut down energy use and costs in HVAC systems.

Refrigerants and Environmental Considerations

Modern HVAC cooling equipment uses advanced refrigeration system parts. These parts balance performance with care for the environment. The change in refrigerants is a big deal for makers and green experts.

Refrigerants are key to cooling systems’ efficiency. But, their effect on the environment is now a big concern. Knowing about these parts can help you choose greener options.

Modern Refrigerant Options

New refrigerant tech brings big improvements. Key advances include:

- Low global warming impact (GWP) options

- Natural refrigerants

- Synthetic refrigerants that are better for the planet

Environmental Impact

Two main factors show how green a refrigerant is:

- Ozone Depletion (ODP): How much it harms the ozone layer

- Global Warming (GWP): Its effect on greenhouse gases

Regulatory Compliance

The HVAC world has strict rules for refrigerant use. Your cooling system parts must meet tough green standards. These standards keep getting stricter.

The future of cooling tech relies on green refrigerant solutions.

Companies are putting more into research. They aim to make cooling systems that are good for the planet and work well.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopInstallation and Maintenance Requirements

Getting your commercial chiller units installed and maintained right is key. It ensures your HVAC system works its best. Spending time and money on professional setup and regular upkeep can make your equipment last longer. It also helps avoid expensive repairs.

When you install commercial chiller units, a few things matter a lot:

- Choosing the right size for your space

- Finding the best spot with good air flow

- Connecting it well with your current HVAC system

- Following the maker’s instructions

Regular maintenance is vital for a smooth-running HVAC system. Preventive care is always cheaper than fixing things after they break. Your maintenance plan should include:

- Checking the chiller units every month

- Cleaning the condenser coil every quarter

- Checking the refrigerant level and pressure every six months

- Doing a full system check once a year

Experts say to do maintenance when it’s not busy. This way, it doesn’t mess up your building’s work. A good maintenance plan helps save energy, cuts down on unexpected stops, and gets the most out of your chiller units.

Energy Optimization and Cost Savings

Facility managers are now focusing on cutting down energy use in HVAC systems to lower costs. The introduction of variable-speed drive (VSD) technology has greatly improved chiller efficiency. This has opened up new ways to save energy.

Here are some key strategies for better chiller performance:

- Implementing advanced control systems

- Utilizing load-matching technologies

- Performing regular maintenance

- Exploring heat recovery options

Modern chiller systems can cut energy use by up to 40% with smart design and management. How you optimize your system can greatly affect your costs.

“Efficiency is not about spending less, but about investing smartly in your cooling infrastructure.” – HVAC Engineering Professionals

Here are some practical steps to boost chiller efficiency:

- Conduct thorough energy audits

- Install variable speed drives

- Optimize system sequencing

- Monitor real-time performance metrics

By focusing on chiller efficiency and using the latest HVAC technologies, you can save a lot of money. You can also keep your cooling system running at its best.

Conclusion

Understanding what a chiller in HVAC is shows us a key technology for cooling in many fields. Chillers are vital for keeping the right temperature in places like data centers and factories. They help control the environment in commercial and industrial settings.

Centrifugal chiller operation is a big step forward in cooling efficiency. Choosing modern chiller technology can save a lot of energy and help the planet. New refrigerants and designs are making chillers better and greener.

With rising energy costs and stricter green rules, picking the right chiller is more critical than ever. Thinking about cooling power, energy use, and eco-friendliness can save money and cut down on pollution. This smart choice can benefit your business and the environment for years.

The future of HVAC chillers is bright, with new tech for better energy use, smart controls, and less harm to the environment. Keeping up with these advancements means your cooling will work best and help make industries more eco-friendly.