Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How to Design Ducting for HVAC? Are you tired of uneven temperatures and high energy bills? The secret to a comfortable home might be in your ductwork design.

Learning to design ducting for HVAC is key for a comfortable home. The size of your HVAC ducts affects how well air is distributed in your home.

Good duct design is more than just moving air. It’s about making your home comfortable, saving energy, and getting the most from your HVAC system.

Professional HVAC contractors say the right ductwork can make a huge difference. Every choice, from materials to layout, is important for a good duct system.

Key Takeaways

- Proper duct design directly impacts home comfort and energy efficiency

- HVAC duct sizing is critical for optimal air distribution

- Material and layout choices significantly affect system performance

- Effective ductwork reduces energy consumption

- Professional design ensures balanced temperature throughout your home

Table of Contents

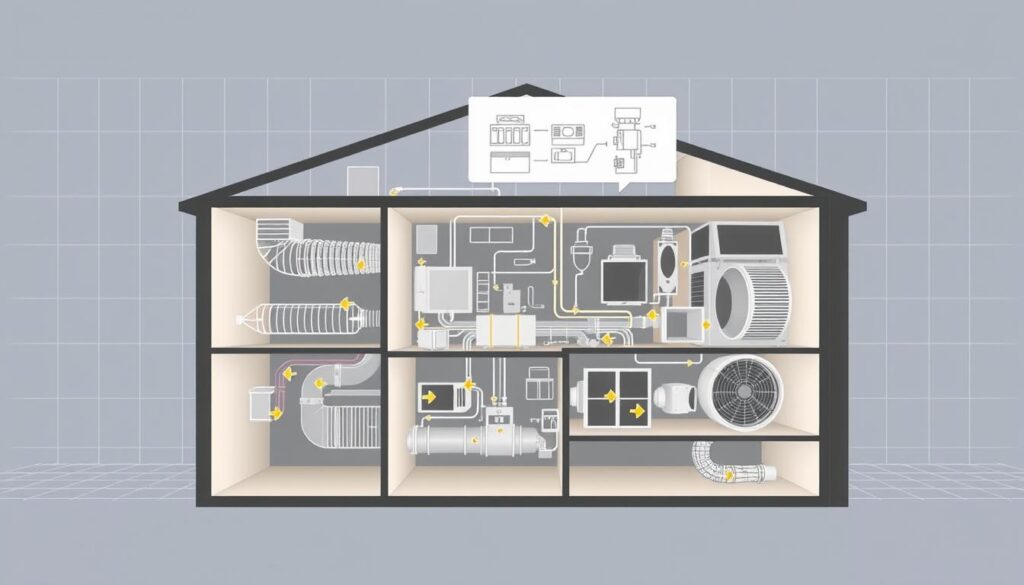

Understanding HVAC Duct Systems Basics

HVAC duct systems are like the lungs of your building. They help move air around for heating, ventilation, and air conditioning. When you design ductwork, you’re working with a complex system.

Key Components of Duct Systems

- Plenums: Central air collection and distribution chambers

- Main trunk ducts: Primary air transportation channels

- Branch ducts: Secondary distribution paths

- Diffusers: Air release points into individual rooms

- Dampers: Air flow control mechanisms

Duct Material Varieties

Sheet metal duct design uses different materials. Each has its own strengths and uses:

- Galvanized Steel: Durable, corrosion-resistant, standard industrial material

- Aluminum: Lightweight, easy to install, great for homes

- Fiberglass: Keeps air warm, absorbs sound

- Flexible Plastics: Good for tricky spaces

Duct System Classifications

Knowing about duct types helps with HVAC design:

| Classification Type | Velocity Range | Pressure Level |

|---|---|---|

| Low Velocity | 500-1000 feet/minute | Low pressure |

| Medium Velocity | 1000-2000 feet/minute | Medium pressure |

| High Velocity | 2000-4000 feet/minute | High pressure |

Choosing the right duct design depends on your building, climate, and energy goals.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopHow to Design Ducting for HVAC

Creating a good HVAC duct system needs careful planning and technical skills. Your ductwork layout is key for the best air flow and system efficiency. Knowing how to design ducting for HVAC helps make a top-notch ventilation system.

Design Principles and Fundamentals

Good HVAC duct sizing starts with a few important steps:

- Reduce air resistance and pressure drops

- Make sure airflow is balanced

- Choose the right duct materials and shapes

- Use space wisely

Pressure and Velocity Considerations

“The secret to efficient ductwork is understanding the delicate balance between air pressure and velocity.” – HVAC Engineering Expert

When making HVAC ducts, managing air velocity and pressure is key. Too much velocity can make noise and use more energy. Not enough velocity means the system won’t work well.

| Design Factor | Optimal Range | Impact on System |

|---|---|---|

| Air Velocity | 600-900 feet per minute | Balanced airflow and minimal noise |

| Static Pressure | 0.1-0.5 inches of water column | Efficient energy performance |

| Duct Sizing | Matches room requirements | Optimal air distribution |

Sizing and Layout Guidelines

Good hvac duct sizing needs a methodical approach. Think about room size, heat load, and airflow needs when picking duct sizes. There are three main ways to size ducts:

- Constant Friction Loss Method: Keeps pressure drop the same in all duct parts

- Velocity Reduction Method: Changes duct size to slow air down

- Static Regain Method: Deals with pressure changes in complex duct systems

Selecting the Right Duct Shapes and Materials

Choosing the right duct shape and material is key for efficient ductwork systems. The design of your HVAC system affects its performance, cost, and overall effectiveness.

Duct shapes are important in sheet metal duct design. There are three main types:

- Round ducts

- Rectangular ducts

- Oval ducts

Round ducts are the most aerodynamic, reducing air resistance and boosting airflow. They need less material and allow for smoother air flow than rectangular ducts.

| Duct Material | Pros | Cons |

|---|---|---|

| Galvanized Steel | Durable, long-lasting | Heavy, possible rust |

| Aluminum | Light, resistant to corrosion | More expensive |

| Fiberglass | Insulates well, reduces noise | Less durable, might release fibers |

When picking materials for ductwork, think about the environment, budget, and project needs. Aluminum is good for light applications, while galvanized steel is the most durable.

Your choice of duct shape and material affects system performance, energy use, and maintenance costs. Carefully choose to design the best HVAC solution.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopSupply Duct Configurations and Installation

Creating effective commercial and residential duct designs needs a grasp of different supply duct setups. Each setup has its own benefits for various building shapes and airflow needs.

Choosing the right duct setup is key for a successful HVAC installation. Experts usually pick from three main types:

- Extended Plenum Systems

- Radial and Spider Systems

- Perimeter Loop Systems

Extended Plenum Systems

Extended plenum systems fit well in rectangular areas with steady airflow needs. They have a main duct with smaller ducts leading to each register. These systems offer balanced air distribution and are budget-friendly for many projects.

Radial and Spider Systems

Radial systems, also known as spider systems, have a central hub with ducts spreading out. This setup is great for flexible layouts, allowing for precise airflow control and less pressure loss.

| System Type | Best Applications | Key Advantages |

|---|---|---|

| Extended Plenum | Rectangular spaces | Consistent airflow, cost-effective |

| Radial/Spider | Flexible layouts | Precise control, minimal pressure loss |

| Perimeter Loop | Large commercial spaces | Uniform temperature distribution |

Perimeter Loop Systems

Perimeter loop systems are best for big commercial areas. They ensure even temperature around the building edges. This helps keep comfort levels consistent in large spaces.

Choosing the right duct setup needs a close look at your space, airflow needs, and building type.

Ductwork Pressure Loss Calculations

It’s key to know how to calculate hvac duct pressure loss for efficient ductwork systems. Pressure loss happens when air flows through ducts, causing resistance. This affects how well the HVAC system works. Experts must look at many factors to get the best airflow and system performance.

Important things that affect pressure loss include:

- Duct material and surface roughness

- Duct geometry and shape

- Air velocity and flow rate

- Length and configuration of ductwork

- Number and type of fittings

There are two main ways to figure out pressure loss: the equal friction method and the static regain method. The equal friction method helps find the right duct sizes by keeping friction rates the same everywhere. This method keeps air resistance even and stops performance problems.

When doing hvac duct pressure loss calculations, you need to:

- Measure the airflow volume needed

- Calculate friction loss per 100 feet of ductwork

- Consider pressure drops in bends and fittings

- Look at the total system resistance

Professional HVAC designers use special software and engineering to make efficient ductwork systems. They aim to reduce pressure losses. By understanding these concepts, you can design systems that improve airflow, cut energy use, and boost HVAC performance.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopEfficient Airflow Distribution Strategies

Getting the airflow right in ducts is key for comfy and energy-saving HVAC systems. Your duct planning should aim for smart ways to move air well and save energy.

Good airflow needs a detailed plan that looks at many factors. You must balance several important things to make your ventilation system work well.

Balancing Supply and Return Air

Having the right air balance is essential for HVAC success. Here are some key strategies:

- Keep air pressure steady in all zones

- Make sure return and supply air volumes are equal

- Reduce pressure differences between rooms

Zoning Considerations for Optimal Performance

Good duct planning means making different thermal zones that fit your building. Your plan should include:

- Find out what temperature each zone needs

- Set up separate controls for each zone

- Use zone-specific airflow management

Optimizing Air Distribution

To get the most out of duct airflow, focus on where you put diffusers and grilles:

| Location Type | Airflow Efficiency | Recommended Strategy |

|---|---|---|

| Open Floor Plans | High | Centralized diffuser placement |

| Multi-Room Spaces | Medium | Zoned distribution systems |

| Complex Layouts | Low | Custom airflow mapping |

Pro tip: Regular checks keep your airflow system running smoothly and avoid losing efficiency.

HVAC Duct System Maintenance and Testing

Keeping your ductwork systems in good shape is key for your commercial HVAC ducting’s long-term success. Regular upkeep stops problems before they start. It also keeps the air clean and saves energy.

There are a few important steps to keep your HVAC system working well:

- Do thorough duct inspections

- Clean the ductwork well

- Look for air leaks and seal them

- Check airflow and pressure levels

Make sure to include specific tests in your maintenance plan. Experts say to check your system often to catch issues early. These tests usually cover:

- Airflow measurement tests

- Pressure system evaluations

- Leak detection scanning

- Insulation integrity checks

Commercial HVAC ducting needs extra care. Look out for early signs of trouble, like:

- Unusual noise when it’s running

- Less airflow than usual

- Dust or debris showing up

- Temperatures not staying even

Regular maintenance can cut energy costs by up to 15% and make your HVAC system last longer.

Choose professional maintenance services to keep your ductwork systems running smoothly. This avoids expensive fixes and keeps the air inside clean and healthy.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopCommon Ductwork Design Mistakes to Avoid

Creating an efficient duct system for your home needs careful planning. Knowing how to design ducting for HVAC helps avoid mistakes. This improves your system’s performance and saves energy.

There are key errors that can make your HVAC ductwork less effective. Knowing these mistakes helps you build a better system.

- Undersizing Ducts: Narrow ducts limit airflow, leading to higher energy use and lower system performance. It’s important to size ducts correctly in residential duct design.

- Excessive Flexible Duct Usage: Flexible ducts are handy but can block airflow if used too much or installed wrong.

- Poor Duct Sealing: Leaks in ducts waste energy and lower system efficiency. Sealing ducts well keeps air from leaking and keeps performance up.

- Inadequate Insulation: Ducts without enough insulation lose a lot of energy, which is bad, even in unheated areas.

To make your HVAC ductwork better, use accurate measurements, quality materials, and expert installation. Talking to HVAC pros can help you avoid common mistakes in duct design.

“The difference between a good and great HVAC system often lies in the details of duct design.” – HVAC Engineering Professionals

By focusing on these design mistakes, you can make your HVAC system more efficient, reliable, and cost-effective for your home.

Conclusion

Designing efficient ductwork systems is key for good HVAC performance. It’s important to pick the right materials and layout. Your duct design affects system efficiency, energy use, and air quality.

Professional HVAC designers know that ductwork is more than just installing it. By using the tips from this guide, you can make systems that improve airflow and comfort. This can also save energy and make systems last longer.

Creating efficient ductwork systems needs ongoing learning and attention to detail. Whether it’s for homes or businesses, this knowledge helps make better design choices. Your focus on HVAC duct design will lead to more reliable and effective ventilation.

Every HVAC system is different, so a custom approach is needed. Spend time on planning, choose quality materials, and focus on the right size and layout. This way, you’ll make duct systems that work well and keep buildings comfortable for years.