Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How to Calculate Static Pressure in HVAC System? Ever wondered why your HVAC system isn’t working as well as it should? The answer might be in understanding static pressure in HVAC systems. Static pressure is the resistance air faces as it moves through ductwork. Learning how to measure it can greatly improve your system’s performance.

Measuring static pressure in ductwork is key to keeping your heating and cooling at its best. Both pros and homeowners need to grasp this important tool. It helps spot airflow problems and system limits.

Getting static pressure right gives you a peek into your HVAC’s health. It shows if there are blockages, design flaws, or faulty parts. These issues can affect your comfort and energy use.

Key Takeaways

- Static pressure measures airflow resistance in HVAC systems

- Proper measurement helps diagnose system performance issues

- Understanding static pressure can improve energy efficiency

- Regular pressure testing prevents potential system failures

- Professional tools are essential for accurate measurements

Table of Contents

Understanding Static Pressure in HVAC Systems

Static pressure is key to your HVAC system’s performance. It affects your home’s comfort and energy use. Knowing how air moves in your system is vital for its best function.

Static pressure is the air’s resistance as it goes through ducts, filters, and other parts. The hvac static pressure formula lets techs check air flow in your home.

Defining Static Pressure

Static pressure is like blood flow in veins. More resistance means the system has to work harder. High static pressure can lead to:

- Less efficient airflow

- More energy use

- Strain on equipment

- Uneven temperatures

Importance of Measurement

Calculating total static pressure is key to finding system problems. Techs use special tools to measure pressure. This ensures your HVAC system works its best.

“Proper static pressure measurement is like a health checkup for your HVAC system.” – HVAC Professional

System Efficiency Impact

A balanced system with right static pressure saves energy and extends equipment life. By keeping an eye on static pressure, you protect your investment and keep your home comfy.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopHow to Calculate Static Pressure in HVAC System

Knowing how to calculate static pressure is key for a well-working HVAC system. It helps spot problems in your duct system and keeps air flowing well. This is important for both heating and cooling.

Static Pressure Formula Basics

To figure out static pressure, you need to use a special tool called a manometer. It helps find out how hard it is for air to move through your system.

- Static Pressure = Total External Static Pressure (TESP)

- Measured in inches of water column (in. w.c.)

- Calculated by combining supply and return side readings

Essential Measurement Tools

To check your HVAC system’s health, you’ll need certain tools:

| Tool | Purpose | Accuracy |

|---|---|---|

| Digital Manometer | Measure air pressure differences | ±0.01 in. w.c. |

| Pitot Tube | Locate test ports | High precision |

| Pressure Taps | Access measurement points | Critical for accurate readings |

Step-by-Step Calculation Process

- Identify test ports in supply and return sides

- Connect digital manometer to test ports

- Record pressure readings at each point

- Add supply and return pressure measurements

- Compare result with manufacturer specifications

By following these steps, you can find and fix any air flow problems. This makes your HVAC system work better.

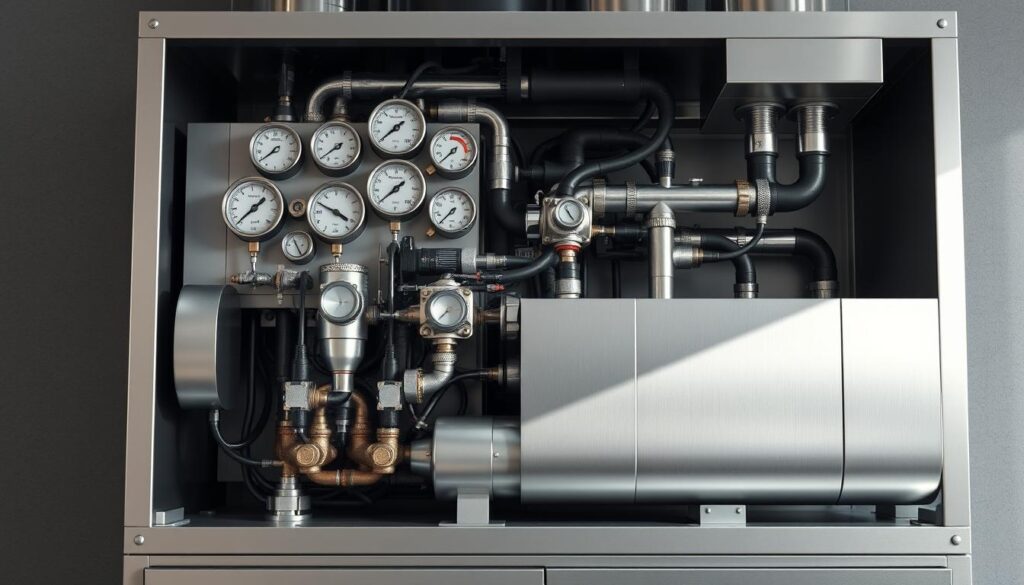

Essential Tools and Equipment for Static Pressure Testing

To get accurate results in HVAC systems, you need special tools. A manometer is key for measuring system performance. It helps ensure the HVAC system is balanced.

- Digital or analog manometer

- Static pressure test ports

- Drill bits for creating measurement holes

- Flexible measurement tubing

- Protective safety equipment

Manometers are either digital or analog. Digital ones show exact readings on an electronic screen. Analog ones use mechanical parts for measurements. Your choice depends on your needs and budget.

| Tool | Purpose | Recommended Accuracy |

|---|---|---|

| Digital Manometer | Precise pressure measurement | ±0.1 inches water column |

| Static Pressure Tips | Creating test measurement points | Stainless steel recommended |

| Calibration Kit | Ensuring measurement accuracy | Annual recalibration suggested |

Choosing top-notch, well-kept tools is crucial for accurate tests. Make sure your equipment is calibrated and ready to use before you start.

Professional tip: Invest in reliable measurement tools to guarantee precise HVAC system performance assessments.

Remember, safety is key during testing. Always wear the right protective gear and follow the tool’s instructions when working in HVAC systems.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

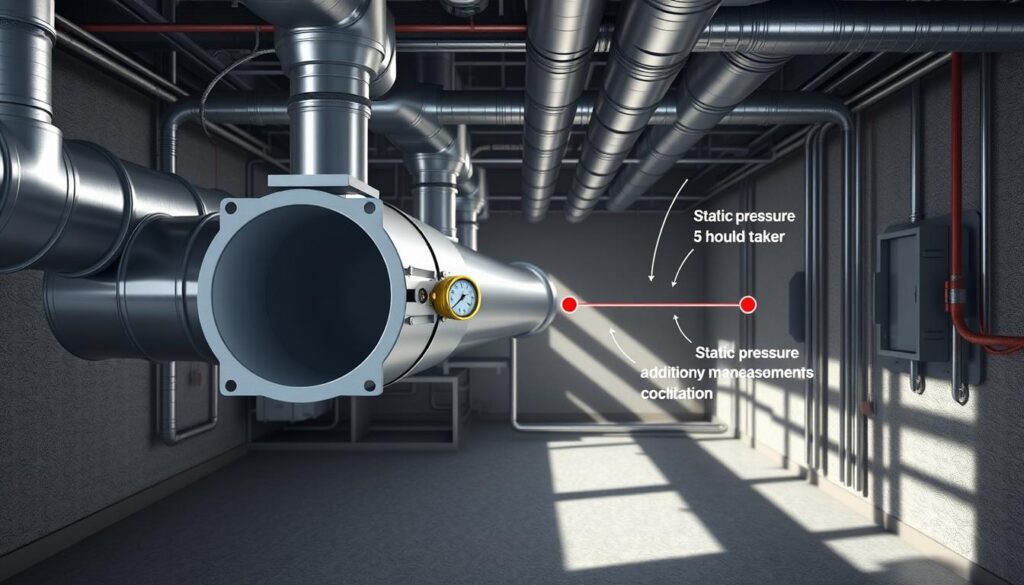

Visit the ShopStatic Pressure Measurement Locations

Knowing where to measure static pressure in ductwork is key for a good HVAC system. It helps find and fix problems and makes sure air flows right in your space.

Technicians check a few important spots to understand how well the system works. These spots show if there are problems with air flow.

Supply Side Testing Points

Measuring static pressure here checks how well air is delivered. Technicians look at:

- Directly after the air handler

- Before supply registers

- At main supply trunk lines

Return Side Testing Points

Measuring here checks air flow and if there are system problems. Key spots include:

- Near the return air grille

- At the return duct entrance

- Before the air handler intake

Filter and Coil Pressure Points

Measuring pressure here tells us about system efficiency and if there are blockages:

| Component | Measurement Location | Typical Pressure Drop |

|---|---|---|

| Air Filter | Before and after filter | 0.1 – 0.5 inches WG |

| Cooling Coil | Inlet and outlet | 0.2 – 0.6 inches WG |

| Heating Coil | Inlet and outlet | 0.1 – 0.4 inches WG |

Getting accurate readings at these spots helps find and fix system problems. It also tells us when maintenance is needed.

Common Static Pressure Issues and Solutions

Static pressure problems can really hurt your HVAC system’s performance. Knowing about these issues helps keep your ducts and system in top shape. This ensures your home stays comfortable and saves on energy.

High static pressure is a big problem for your HVAC system. It makes your equipment work too hard. This can lead to breakdowns and higher energy bills.

- Reduced airflow through vents

- Higher energy bills

- Premature equipment wear

- Inconsistent room temperatures

What causes static pressure issues? Here are a few common reasons:

- Undersized ductwork that blocks air flow

- Clogged air filters that stop air from moving

- Blocked or closed air vents

- Bad design of your HVAC system

Figuring out static pressure problems needs a pro. An HVAC tech can check pressure levels and find out what’s wrong with your system’s balance.

Proactive maintenance prevents 70% of potential HVAC performance problems related to static pressure.

To fix these issues, you might need to clean or replace filters, seal duct leaks, and make sure ducts are the right size. Regular checks by a pro can spot problems early, saving you from costly repairs.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopStatic Pressure vs. Velocity Pressure in HVAC Systems

Understanding pressure in HVAC systems is key for top performance and efficiency. Two main pressure types are involved: static pressure and velocity pressure.

Static pressure vs. velocity pressure are two main ideas in air systems. Static pressure shows air’s potential energy in ducts. Velocity pressure shows air’s energy when it moves.

Understanding the Differences

Here are the main differences:

- Static pressure measures air’s potential energy at rest

- Velocity pressure indicates air’s movement energy

- Total static pressure calculation combines both pressure types

- Pressure measurements impact overall system efficiency

Total Pressure Calculations

Total pressure in HVAC systems is static and velocity pressure added together. Experts use special tools to measure these pressures for the best system performance.

System Balance Considerations

It’s important to balance static and velocity pressure. You need to keep the right pressure levels to:

- Maximize airflow efficiency

- Reduce energy consumption

- Prevent system strain

- Optimize overall HVAC performance

Proper pressure management ensures your HVAC system operates at peak effectiveness, delivering consistent comfort and energy efficiency.

Manufacturer Specifications and Requirements

Understanding air handler static pressure requirements is key for your HVAC system’s best performance. Manufacturers give specific guidelines. These help keep your system running safely and efficiently.

Every HVAC equipment maker has its own static pressure range specs. These are important because they affect how long your system lasts and how well it works. If you don’t follow these specs, you might face big issues:

- Potential warranty voiding

- Reduced system efficiency

- Increased wear and tear on components

- Higher energy consumption

The hvac static pressure formula is crucial for safe operation. Makers use tests and research to set these ranges. You can find these in your equipment’s manual or technical guides.

To keep your system in top shape, follow these steps:

- Find the specs for your HVAC unit from the manufacturer

- Check and confirm static pressure regularly

- Get a pro to check your system

- Fix any pressure issues right away

Pro tip: Always get help from professional HVAC techs. They know how to follow the manufacturer’s rules and keep your system at the right static pressure.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopOptimizing HVAC System Performance Through Pressure Control

To get the most out of your HVAC system, you need to control pressure well. Managing duct sizing and static pressure can make your system work better, feel more comfortable, and last longer.

Effective pressure management is key. It involves many important factors that affect how well your system works. Your HVAC system’s success depends on balanced parts and smart design choices.

Ductwork Design Considerations

Duct sizing and static pressure are vital for system performance. When designing ductwork, keep these points in mind:

- Reduce bends and restrictions

- Choose the right duct materials

- Size ducts for best airflow

- Keep cross-sectional area consistent

System Component Selection

Picking the right parts is crucial for keeping pressure balanced. Think about these important factors:

- Choose fans with the right performance curves

- Use high-efficiency filters

- Match coil and air handler specs

- Check pressure drop across components

Maintenance Requirements

Regular upkeep keeps your system running smoothly. Important maintenance steps include:

- Change filters every quarter

- Get annual professional checks

- Clean ducts to avoid blockages

- Check and calibrate pressure sensors

By following these tips, you can improve your HVAC system’s performance. This will lower energy use and make your equipment last longer.

Conclusion

Knowing how to calculate static pressure in HVAC systems is key for comfort and efficiency. It affects energy use, system life, and air quality. HVAC experts see precise pressure control as essential, not just a detail.

To keep your HVAC system in balance, you need to watch it closely and maintain it well. Using the methods and tools from this article helps spot problems early. Regular checks help improve airflow, lower wear on parts, and keep your system running smoothly.

Learning about static pressure can save you money and make your system last longer. It also makes your space more comfortable. Whether you work in HVAC, manage buildings, or own property, focusing on pressure is wise.

Remember, managing static pressure is an ongoing task. Keep learning, follow the latest practices, and always value accurate pressure calculations. They’re crucial for efficient, dependable HVAC systems.