Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

Ever wondered why your HVAC system isn’t working as well as it should? The answer might be in a small but key part called the thermostatic expansion valve (TXV). Could a simple tweak unlock your system’s full power?

How to Adjust HVAC Expansion Valve? Knowing how to adjust an HVAC expansion valve is key to keeping your system running smoothly. This small but vital part helps control how much refrigerant flows. It makes sure your cooling system works at its best.

Experts in HVAC know that adjusting the thermostatic expansion valve right can really improve how well your system works. The valve’s design lets it keep the superheat constant. This balance is important for controlling how the refrigerant moves through your system.

Key Takeaways

- TXV adjustment requires precise technical knowledge

- Proper valve settings impact overall system efficiency

- Incorrect adjustments can lead to system performance issues

- Regular maintenance prevents unexpected breakdowns

- Understanding valve mechanics is crucial for HVAC professionals

Table of Contents

Understanding HVAC Expansion Valve Operation

Your HVAC system needs precise refrigerant management. The thermostatic expansion valve (TXV) is key to this. Knowing how it works helps with troubleshooting and repair.

The expansion valve connects the high-pressure and low-pressure sides of your cooling system. It turns liquid refrigerant into a low-pressure, low-temperature gas. This makes it efficient at absorbing heat.

Key Components of a TXV

- Sensing bulb: Monitors refrigerant temperature

- Diaphragm: Controls refrigerant flow

- Spring mechanism: Regulates valve opening

- Inlet and outlet ports: Manage refrigerant movement

Working Principles

The TXV keeps a constant superheat value at the evaporator outlet. This ensures the system works well and prevents liquid refrigerant from getting into the compressor.

| Component | Function | Importance |

|---|---|---|

| Sensing Bulb | Temperature monitoring | Ensures proper refrigerant flow |

| Diaphragm | Flow control | Prevents system overload |

| Spring | Pressure regulation | Maintains consistent performance |

System Performance Impact

A working expansion valve boosts your HVAC system’s efficiency. It controls refrigerant flow, protects the compressor, and keeps cooling steady. Regular maintenance stops system failures and extends life.

Essential Tools and Safety Precautions

When you replace an expansion valve or check your HVAC system, the right tools and safety gear are key. Professional HVAC techs know how important it is to get ready before starting any job.

- Refrigerant pressure gauges

- Digital thermometer

- Specialized wrench set

- Protective safety glasses

- Insulated electrical gloves

- Refrigerant leak detector

Keeping safe is very important when you replace an expansion valve. Always wear the right protective gear and follow the maker’s rules to avoid dangers. Refrigerants can be harmful if not handled right, so knowing the right ways is key.

| Safety Equipment | Purpose |

|---|---|

| Safety Glasses | Protect eyes from refrigerant splash |

| Insulated Gloves | Prevent electrical shock |

| Respirator Mask | Prevent inhalation of refrigerant gases |

Before you start any HVAC checks, make sure you’re trained and certified. Local laws need you to have special skills for working with refrigeration systems. Spend time learning about your tools and safety rules to keep yourself safe and the system working well.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopPre-Adjustment System Inspection

Before you start calibrating the heat pump expansion valve, a detailed system check is key. This step is vital for fine-tuning your air conditioning. It helps make sure your HVAC system works at its best.

Checking Subcooling Levels

Subcooling is important for your HVAC system’s health. You must check the liquid refrigerant’s temperature at the expansion valve. Here’s how:

- Measure the liquid line temperature

- Compare it to the manufacturer’s specs

- Make sure the refrigerant is in the right state

Verifying Pressure Differential

Pressure differential is crucial for air conditioning tuning. Your check should include:

- Measuring inlet and outlet pressures

- Figuring out the pressure drop across the expansion valve

- Matching it with the system’s design

| Inspection Parameter | Ideal Range | Action Required |

|---|---|---|

| Subcooling Temperature | 10-12°F | Adjust refrigerant charge |

| Pressure Differential | 100-150 PSI | Check expansion valve operation |

Inspecting Bulb Placement

The placement of the thermostatic expansion valve (TXV) bulb is critical. Wrong placement can cause big problems. Make sure the bulb is:

- Attached securely to the suction line

- At the right pipe spot

- Insulated from outside temperatures

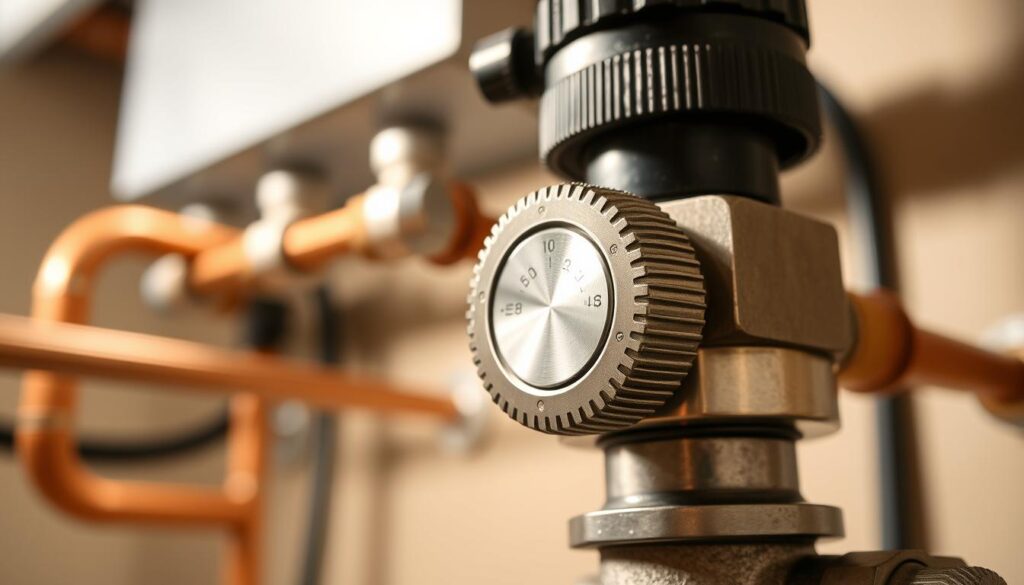

How to Adjust HVAC Expansion Valve

Adjusting an HVAC expansion valve needs precision and attention to detail. Before starting, understand the basics and steps for adjusting the valve settings.

First, check if your expansion valve can be adjusted. Not all valves can be adjusted, so look at your system’s manufacturer guidelines. Safety is paramount during this process.

- Gather necessary tools including:

- Thermometer

- Pressure gauges

- Wrench set

- Verify system stability before making any adjustments

- Understand superheat measurement principles

When adjusting the valve, remember these key points:

- Turning the adjustment stem clockwise increases superheat

- Turning counterclockwise decreases superheat

- Make incremental quarter-turn adjustments

- Allow system 10-15 minutes to stabilize after each adjustment

“Precision is key in expansion valve adjustment. Small changes can significantly impact system performance.” – HVAC Professional Handbook

Monitor system performance after each adjustment. Measure superheat levels often to ensure optimal operation. If unsure about any step, consider consulting a professional HVAC technician.

Proper TXV Bulb Installation and Positioning

The thermostatic expansion valve (TXV) bulb is key in HVAC txv troubleshooting. It needs precise installation for your system’s best performance. How well you install and protect this device affects your system’s efficiency.

Installing the TXV bulb right involves several important steps. These steps help ensure your system works well and needs less repair:

- Select the correct suction line location

- Ensure direct contact with the pipe surface

- Use appropriate mounting straps

- Protect from external temperature variations

Correct Mounting Techniques

When you install the TXV bulb, make sure it’s tightly and flatly connected to the suction line. Place the bulb on the bottom or side of the pipe for accurate temperature sensing. Use a good mounting strap that applies even pressure without harming the bulb or pipe.

Insulation Requirements

Insulation is not optional for TXV bulb installation. Without it, temperature readings and system performance can be affected. Choose insulation that:

- Provides thermal protection

- Resists moisture

- Fits snugly around the bulb and pipe

- Can handle typical HVAC operating temperatures

Correct bulb installation and insulation are vital. They help keep your HVAC system efficient and prevent repair issues with the refrigerant expansion valve.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopUnderstanding Superheat Settings and Adjustments

Adjusting superheat settings is key for your air conditioning to work its best. Superheat is when the refrigerant vapor gets hotter than it should after leaving the evaporator. Getting these settings right can make your HVAC system more efficient and last longer.

When you’re tuning your air conditioning, you need to get the superheat just right. It should be between 5-8 degrees, but this can change based on the maker’s advice.

- Measure refrigerant temperature at the evaporator outlet

- Compare with saturated suction temperature

- Calculate the difference to determine superheat

If you can’t measure the evaporator directly, you’ll have to use pressure readings instead. Getting the superheat just right is crucial for your system’s performance and avoiding damage to the compressor.

| System Type | Typical Superheat Range | Recommended Action |

|---|---|---|

| Residential AC | 5-8 degrees | Verify manufacturer specifications |

| Commercial HVAC | 8-10 degrees | Perform detailed system analysis |

Things like the outside temperature, how much work the system is doing, and how much refrigerant it has affect superheat. Experts need to look at these factors closely when they adjust the superheat to keep your system running at its best.

Troubleshooting Common TXV Issues

Checking the thermostatic expansion valve (TXV) is key in HVAC system diagnostics. Knowing common problems helps you fix them fast. This keeps your system running smoothly.

Identifying Valve Restrictions

Valve restrictions can really slow down your HVAC system. Look out for these signs:

- Reduced refrigerant flow

- Unusual system noise

- Inconsistent cooling performance

- Frost buildup on suction line

Dealing with Low Suction Pressure

Low suction pressure is a big problem in HVAC diagnostics. It can be caused by:

- Clogged inlet screens

- Damaged valve components

- Refrigerant contamination

- Incorrect bulb positioning

System Performance Problems

Figuring out TXV performance issues needs a careful check. Here’s how to do it:

| Symptom | Potential Cause | Recommended Action |

|---|---|---|

| High Superheat | Valve Underfeeding | Check TXV adjustment |

| Low Superheat | Valve Overfeeding | Inspect bulb placement |

| Inconsistent Cooling | Valve Restriction | Clean or replace valve |

Not all TXV problems can be fixed easily. Sometimes, you need a pro to check your system.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopMaintaining Optimal Valve Performance

To keep your HVAC system’s expansion valve working well, you need a good maintenance plan. Taking care of it can make it last longer and save you money on repairs.

Regular maintenance is key for the best performance:

- Do a visual check of the expansion valve every quarter

- Look for any wear or damage

- Make sure the refrigerant levels are right

- Clean and protect the valve parts

It’s also important to have a detailed maintenance plan. Keep a log that tracks:

| Maintenance Aspect | Recommended Frequency | Key Indicators |

|---|---|---|

| Visual Inspection | Quarterly | Corrosion, physical damage |

| Refrigerant Check | Bi-annually | Pressure levels, system efficiency |

| Performance Evaluation | Annually | Superheat settings, overall system performance |

Watch out for things that might harm your expansion valve. Extreme temperatures, humidity, and dust can wear it down faster. Experts say to get your heat pump checked regularly to avoid big problems.

Preventative maintenance is always more cost-effective than emergency repairs.

Today’s HVAC systems are getting more advanced. Think about getting smart monitoring tools. They can give you updates on your expansion valve’s health, helping you fix issues early.

Conclusion

Adjusting an HVAC expansion valve needs precision and technical knowledge. Knowing how to adjust these valves can greatly improve your system’s performance and energy use. This article has given you the tools to diagnose and fix valve issues.

Professional HVAC system checks are vital for keeping your system running well. While this guide is helpful, some adjustments need expert skills. Trained technicians can spot issues that you might miss.

The HVAC field is always changing. Keeping up with new tech, attending workshops, and following industry standards will improve your skills. Remember, regular maintenance and precise adjustments are key to a long-lasting system.

Always put safety first and seek professional help when dealing with complex HVAC parts. If you’re unsure, get advice from certified experts. They can help make sure your system works at its best.