Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How HVAC Chiller Works? Ever wondered how big buildings stay cool without sweating? The answer is in the complex world of HVAC chiller systems.

HVAC chiller technology is a smart way to control temperatures. These systems move heat away from areas that need cool air. They use cool technology that’s more than just air conditioning.

Exploring HVAC chillers, you’ll see a network of parts that remove heat well. Unlike simple coolers, these systems use water or special liquids to keep temperatures just right.

The heart of HVAC chillers is a cool refrigeration process. It turns heat into a cycle that’s easy to handle. In places like hospitals, malls, or factories, these systems keep things comfy.

Key Takeaways

- HVAC chillers use advanced heat transfer technologies

- Multiple components work together to regulate temperature

- Water-based cooling offers superior efficiency

- Chillers can reduce cooling costs by up to 30%

- Different types of chillers suit various environmental needs

Table of Contents

Understanding HVAC Chiller Fundamentals

HVAC chiller systems are key in modern cooling, mainly for big commercial and industrial places. These machines are vital for keeping the right temperature and environment in many settings.

Commercial HVAC systems use about 19% of all U.S. energy. Air conditioning and heating make up 39% of a building’s energy use. Chillers power these big cooling jobs.

What is a Chiller System?

A chiller system is a complex cooling machine. It uses a vapor-compression or absorption refrigeration cycle to cool liquid. It keeps areas cool by circulating coolant at around 50°F (10°C).

Basic Principles of Chiller Operation

- Uses refrigeration cycle to move heat

- Keeps large areas cool

- Works with different types of chillers

- Controls temperature precisely

Role in Commercial Building Cooling

Chillers are key for managing temperature in complex places. They are important in:

- Medical facilities needing strict temperature control

- Data centers protecting sensitive equipment

- Manufacturing plants keeping process conditions

- Large commercial buildings needing lots of cooling

“Chillers are the backbone of modern temperature management, providing unparalleled precision in cooling technology.”

The U.S. Department of Energy says chillers make up about 20% of North America’s electric power. This shows their big role in energy.

How HVAC Chiller Works

It’s important to know how an HVAC chiller works to understand its role in cooling commercial spaces. The hvac chiller refrigeration cycle is a complex process. It efficiently removes heat from buildings and industrial areas.

An HVAC chiller uses a remarkable heat transfer mechanism. It changes refrigerant through several stages. This creates a continuous cooling process that keeps environments comfortable.

- Compressor starts the refrigeration cycle

- Refrigerant changes from liquid to gas

- Heat is effectively transferred

- Cooling happens through pressure manipulation

The refrigeration cycle has four main parts working together:

| Component | Primary Function |

|---|---|

| Compressor | Increases refrigerant pressure and temperature |

| Condenser | Releases heat to the outside |

| Expansion Valve | Reduces refrigerant pressure |

| Evaporator | Takes heat from the surrounding space |

“The magic of cooling lies in the precise dance of refrigerant through its transformation cycle.” – HVAC Engineering Insights

Commercial chillers use this complex process to cool spaces efficiently. Water-cooled or air-cooled systems can use 30% to 50% of a building’s energy. This shows why it’s key to understand HVAC chiller systems.

Modern chiller technologies keep getting better. They focus on saving energy and controlling temperature precisely.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopEssential Components of Chiller Systems

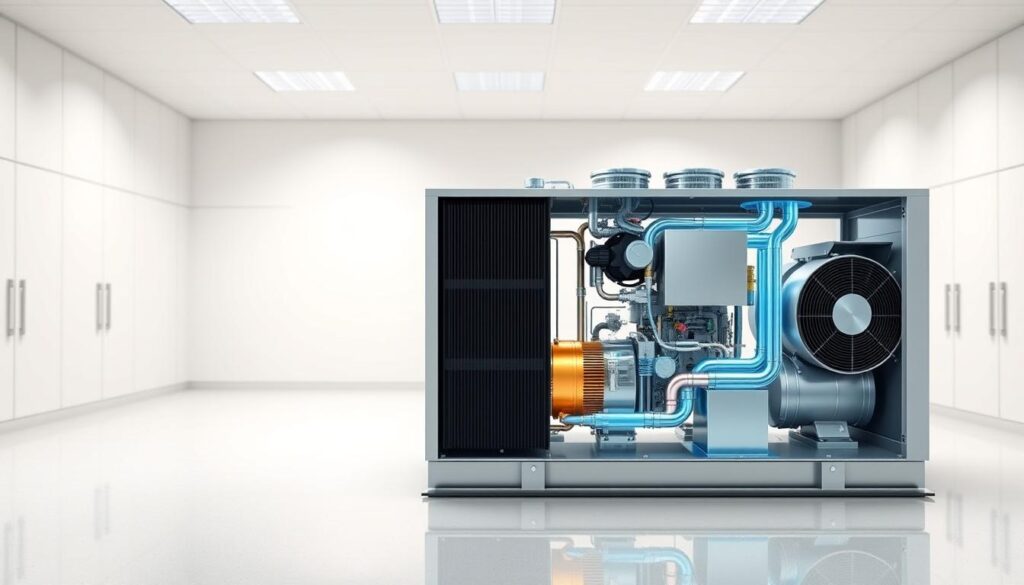

Knowing the main parts of HVAC chiller systems is key for good cooling and temperature control. These machines use several important parts to take heat out of buildings.

Today’s HVAC chillers have complex systems to cool better. Let’s look at the main parts that make these systems strong and dependable.

Evaporator: The Heat Exchange Powerhouse

The evaporator is a key part in chiller systems. It takes heat from the coolant and moves it to the refrigerant, starting the cooling process. Built with tube and shell designs, evaporators are good at pulling heat out of buildings.

Compressor: Driving the Refrigeration Cycle

Compressors are at the heart of chiller systems. They take refrigerant from the evaporator and make the pressure of the outgoing vapor higher. There are different types of compressors for different needs:

- Centrifugal compressors for big systems

- Screw compressors for industrial use

- Scroll compressors for smaller units

- Reciprocating compressors for precise cooling

Condenser: Heat Rejection Mechanism

Condensers are key in moving heat from the refrigerant to outside. There are two main types of chillers:

| Condenser Type | Cooling Method | Typical Application |

|---|---|---|

| Water-Cooled | Uses cooling tower | Large commercial buildings |

| Air-Cooled | Uses ambient air | Smaller facilities |

Expansion Valve: Pressure Regulation

The expansion valve is important for lowering refrigerant pressure. This lets the evaporator absorb heat. Different valve types include thermal expansion, electronic, and fixed orifice designs.

“The success of a chiller system depends on the seamless interaction of its components.” – HVAC Engineering Experts

Each part of HVAC chiller systems works together for efficient cooling in many places.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopThe Complete Refrigeration Cycle Process

Understanding the hvac chiller refrigeration cycle is key to knowing how hvac chiller works. This cycle is a complex thermodynamic process. It makes cooling efficient in many industrial and commercial settings.

- Evaporation: Refrigerant takes in heat and turns from liquid to gas

- Compression: The gas gets pressurized, making its temperature go up

- Condensation: The high-pressure vapor turns back into liquid, releasing heat

- Expansion: The refrigerant’s pressure drops, getting ready for the next cycle

The refrigeration cycle is a continuous process of heat transfer and state changes. It allows for precise temperature control in complex systems.

Each stage uses specific thermodynamic principles to remove heat from the environment. The refrigerant moves through these stages, changing its state and transferring thermal energy efficiently.

| Stage | Process | Key Characteristic |

|---|---|---|

| Evaporation | Heat Absorption | Liquid to Gas Transformation |

| Compression | Pressure Increase | Temperature Elevation |

| Condensation | Heat Rejection | Gas to Liquid Conversion |

| Expansion | Pressure Reduction | Temperature Decrease |

Today’s chillers use this refrigeration cycle in many fields. From food preservation to medical imaging, they show great efficiency and flexibility in cooling technologies.

Water-Cooled Chiller Systems Explained

Water-cooled chiller systems are a top-notch way to cool large areas in industries and businesses. They are designed to handle big cooling jobs across many fields.

These chillers are great at keeping temperatures just right. They use water to cool down, making them very efficient.

Operating Principles

Water-cooled chillers work by a special heat exchange:

- Water flows through a closed system

- Refrigerant moves heat to water in the condenser

- Cooling tower helps get rid of the heat

Advantages and Applications

Water-cooled chillers have big pluses for complex cooling needs:

- They are very efficient in big commercial places

- They work well in all kinds of weather

- Perfect for hospitals, big factories, and data centers

“Water-cooled chillers represent the pinnacle of precision cooling technology” – HVAC Engineering Quarterly

Cooling Tower Integration

Cooling towers are key in water-cooled chiller systems. They help get rid of heat efficiently. This works well with chillers to keep things cool.

Using water-cooled chiller tech, companies can save a lot on energy. They also keep the environment stable in different settings.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopAir-Cooled Chiller Technology

Air-cooled chillers are a key type of HVAC chiller. They use outside air to cool the refrigerant. This makes them great for places where space or water is limited.

“Air-cooled chillers provide a versatile and efficient cooling solution for diverse industrial and commercial settings.” – HVAC Engineering Quarterly

Knowing what air-cooled chillers offer can help you choose the right cooling system. Here are the main benefits:

- Lower installation costs compared to water-cooled systems

- Simplified maintenance requirements

- No need for complex water treatment or cooling towers

- Ideal for outdoor installations

When looking at hvac chiller efficiency, air-cooled systems stand out. They save water and simplify mechanical systems. They’re perfect for smaller spaces, providing precise cooling.

| Air-Cooled Chiller Characteristic | Performance Metric |

|---|---|

| Installation Cost | Lower upfront investment |

| Maintenance Complexity | Reduced technical requirements |

| Water Resource Usage | Minimal to zero consumption |

Choosing an air-cooled chiller can improve your cooling strategy. It keeps your system running well and efficiently.

Energy Efficiency in Chiller Operations

Improving hvac chiller efficiency is key to cutting down energy use and costs in commercial and industrial places. Chillers are a big part of a building’s electrical load. So, making them work better is a big deal for facility managers.

Getting the hang of chiller energy performance can save a lot of money. Industrial chillers use a lot of electricity. Even small improvements can make a big difference in energy use.

Optimization Strategies

To boost hvac chiller energy savings, try these strategies:

- Use variable speed drives to cut down on electricity use

- Keep refrigerant levels just right to avoid losing efficiency

- Keep condenser and evaporator coils clean

- Watch and adjust chilled water supply temperatures

Performance Metrics

Important signs of chiller efficiency include:

- Coefficient of Performance (COP)

- kW per ton of cooling

- Operational load percentages

- Condenser water temperature impact

A chiller with a COP of 6 produces 6 kW of cooling for every 1 kW of electricity consumed.

Cost-Saving Measures

Smart ways to lower operational costs:

- Raise chilled water supply temperature by 2°F to cut energy use by 3-5%

- Use advanced control systems

- Follow regular maintenance schedules

- Try new tech like AI and IoT for better management

By using these tips, you can make your chiller system work better and save on energy costs.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopCommon Chiller System Problems

HVAC chiller troubleshooting is key to keeping your cooling system running smoothly. Spotting and fixing common issues early can save you from expensive repairs. It also ensures your system works at its best.

Operators face many challenges in hvac chiller maintenance. These can hurt your system’s efficiency:

- Electrical connectivity problems

- Refrigerant leaks

- Compressor failures

- Condenser coil contamination

- Control system malfunctions

Not following the right maintenance can harm your chiller. Operators might unknowingly make things worse by skipping maintenance.

“Prevention is always more cost-effective than emergency repairs” – HVAC Engineering Principle

Signs that your chiller might be in trouble include:

| Symptom | Potential Cause | Recommended Action |

|---|---|---|

| Temperature Fluctuations | Refrigerant Level Issues | Professional Inspection |

| High Energy Consumption | Inefficient Operation | System Calibration |

| Unusual Noise | Mechanical Wear | Component Evaluation |

Today’s chillers have fault code displays for quick problem-solving. Knowing these codes helps you fix issues fast, before they get worse.

Maintenance Best Practices

To keep your HVAC chiller system running well, you need a good maintenance plan. Proper care can make your equipment last longer and work better.

Good maintenance is more than just checking things out. It’s about knowing what your system needs and acting early.

Preventive Maintenance Schedule

Having a solid preventive maintenance plan is key to keeping your chiller in top shape. Your plan should include:

- Annual thorough system checks

- Regular checks on refrigerant levels

- Cleaning the condenser coils

- Keeping an eye on water quality

System Monitoring Techniques

Today’s hvac chiller troubleshooting uses new tech to catch problems early. Using real-time monitoring can cut down on unexpected breakdowns by up to 40%.

| Monitoring Parameter | Recommended Frequency | Potential Impact |

|---|---|---|

| Refrigerant Levels | Quarterly | Prevents 20% performance decrease |

| Vibration Analysis | Bi-annually | Prevents costly equipment damage |

| Oil Quality | Annually | Ensures optimal lubrication |

Performance Testing Strategies

Testing your chiller’s performance regularly is vital for keeping it efficient. Key testing methods include:

- Checking thermal efficiency

- Looking at electrical use

- Checking refrigerant pressure

“Preventive maintenance is not an expense, it’s an investment in your chiller’s future performance and reliability.”

By following these maintenance tips, you can cut your utility bills by up to 20%. You can also make your chiller system last longer.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopModern Chiller Innovations

The world of HVAC chillers is changing fast. New technologies are making cooling systems more efficient and effective. These modern systems use advanced tech to control temperature better than ever before.

New types of HVAC chillers are changing how we cool buildings:

- Artificial Intelligence (AI) enabled smart control systems

- IoT-powered real-time monitoring capabilities

- Advanced magnetic bearing compressors

- Variable speed drive technologies

Predictive maintenance is a big deal now. AI helps spot problems before they happen. This cuts down on downtime and saves money on repairs.

“Technology is reshaping cooling systems, making them smarter, more efficient, and environmentally sustainable.” – HVAC Innovation Research Center

Using green energy is also key. Modern chillers work well with solar and wind power. This cuts down on pollution while keeping buildings cool.

The future of chillers looks even brighter. Research is underway for:

- Even better ways to save energy

- Smaller, more flexible systems

- Improved refrigerants

- Smarter network connections

These advancements are more than just tech updates. They’re a big step towards greener, smarter cooling for all industries.

Chiller Applications Across Industries

Chillers are key cooling solutions in many industries. They help control temperatures in various settings. This is true for commercial buildings and specific industrial processes.

Different types of hvac chillers meet unique needs in different sectors:

- Manufacturing: Keeps sensitive equipment cool and product quality high

- Healthcare: Manages temperatures for medical imaging and labs

- Data Centers: Keeps equipment cool to prevent overheating

- Food Processing: Controls temperatures during production and storage

In industrial settings, chillers are vital. They can cool from a few tons to thousands of tons. This makes them flexible for many needs.

“Precise temperature control is not just a luxury, but a necessity in modern industrial processes.”

Many industries use chiller technology, including:

- Semiconductor manufacturing

- Chemical processing

- Pharmaceutical production

- Injection molding

- Laser technology

Chiller technology keeps getting better. It’s now more efficient and eco-friendly. New trends focus on saving energy and using green refrigerants.

Conclusion

Learning about HVAC chillers shows their key role in cooling today’s buildings. Chillers use a lot of electricity, often over 50% in peak times. Knowing how they work helps save energy and cut costs.

The efficiency of HVAC chillers depends on design, upkeep, and new tech. Water-cooled and air-cooled chillers suit different needs. Choosing the right one and keeping it well-maintained can lower energy use and environmental harm.

New chiller tech is all about being green and efficient. Today’s chillers use smart controls and energy-saving parts. As buildings get more complex, knowing about chillers is vital for those who manage them.

Getting a top-notch chiller system is more than just cooling. It’s about making buildings smart, efficient, and kind to the planet. By focusing on chiller efficiency, you help save energy, cut costs, and protect the environment.