Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

What is HVAC Superheat? Ever thought about how your air conditioning system avoids big compressor problems? The answer is HVAC superheat. Knowing about HVAC superheat changes how you care for your cooling system.

Superheat is when refrigerant vapor is hotter than it should be. It’s a key part of HVAC refrigerant superheat calculation. This check makes sure the liquid refrigerant turns fully into gas before hitting the compressor. This keeps your system safe from damage.

Learning about superheat opens up new ways to see how your cooling systems work best. This important process helps avoid damage and keeps your system running smoothly.

Key Takeaways

- Superheat is the temperature of refrigerant vapor above its boiling point

- Proper superheat measurement prevents compressor damage

- HVAC systems rely on precise superheat calculations for performance

- Understanding superheat helps optimize cooling system efficiency

- Superheat is a critical metric in refrigeration cycle management

Table of Contents

Understanding the Fundamentals of HVAC Superheat

Exploring HVAC systems, we find a key concept: what is HVAC superheat. It’s vital for keeping your cooling system working well. It plays a big role in how refrigeration and air conditioning perform.

Superheat is when refrigerant gas gets hotter than its boiling point. It’s the extra heat the refrigerant picks up after turning fully into gas. Knowing about this helps make your cooling system more efficient and keeps it from getting damaged.

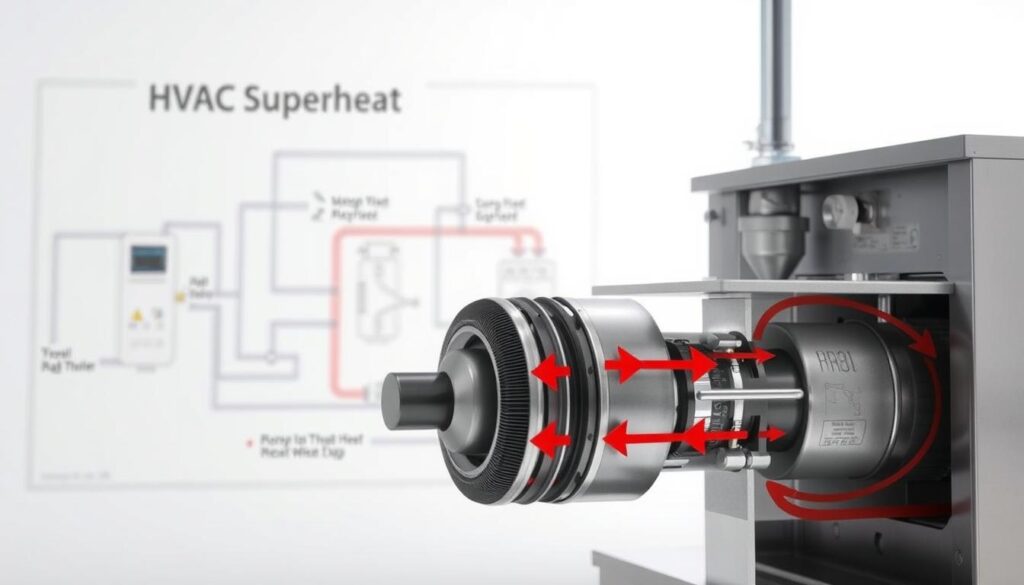

The Physics Behind Superheat Formation

Superheat forms through complex thermodynamic processes. Here’s what happens in the evaporator:

- Refrigerant takes in heat from the air around it.

- Its temperature goes up past its boiling point.

- It turns fully into vapor.

Role of Superheat in Refrigeration Cycle

Superheat and subcooling are two key parts of cooling. Superheat happens in the evaporator, and subcooling in the condenser. Knowing the difference is key for the system to work its best.

Key Components Involved in Superheat Process

Several important parts work together for superheat:

- Evaporator

- Compressor

- Thermostatic expansion valve

- Temperature sensors

By watching and controlling superheat, you can keep your HVAC system running at its best. This protects your investment and keeps the cooling steady.

What is HVAC Superheat: A Comprehensive Guide

Knowing about HVAC superheat is key to keeping your air conditioning running well. Superheat is when the refrigerant vapor gets hotter than its boiling point. This important check makes sure your HVAC system works right and safely.

When checking superheat in air conditioning, techs look at three main things:

- Refrigerant state transformation

- Temperature differential monitoring

- System performance optimization

The science of superheat is about watching the refrigerant’s temperature change from liquid to gas in the evaporator. Proper superheat measurement stops liquid refrigerant from getting into the compressor. This could really hurt the system.

“Superheat is the guardian of your HVAC system’s longevity and performance.” – HVAC Engineering Experts

Superheat has a few important traits:

- Prevents compressor liquid damage

- Indicates refrigerant charge accuracy

- Signals possible system inefficiencies

Experts usually want superheat readings between 5-15 degrees. This depends on the system’s needs and what the maker says.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopThe Critical Role of Superheat in HVAC Systems

Knowing what HVAC superheat is key to keeping your cooling system running well. It’s important for your system’s performance and longevity.

Superheat’s balance is vital for your system’s efficiency and reliability. Setting it right prevents damage and boosts performance.

Protecting Compressor Operation

Your HVAC system’s compressor is its core, and superheat is its protector. It makes sure refrigerant is gas, not liquid, to avoid compressor damage.

- Prevents liquid refrigerant from entering the compressor

- Reduces risk of mechanical failure

- Protects expensive compressor components

Optimizing System Efficiency

Right superheat levels are key to your system’s energy use and cooling power. Too much superheat can lower system performance a lot.

| Superheat Level | System Efficiency Impact |

|---|---|

| Low Superheat (Under 5°F) | Risk of liquid compression |

| Optimal Superheat (8-12°F) | Maximum system efficiency |

| High Superheat (Over 15°F) | Reduced cooling capacity |

Impact on System Longevity

Watching superheat closely can make your HVAC system last longer. It avoids extra stress on parts, saving you money on early replacements.

“Proper superheat management is the key to a healthy, long-lasting HVAC system.” – HVAC Professional Insight

Measuring and Calculating Superheat Values

Knowing how to calculate hvac refrigerant superheat is key for keeping air conditioning systems running well. It’s important to measure superheat accurately. This helps technicians find and fix any issues, making the system more efficient.

To get the superheat right, you need to follow a few steps. The main formula for superheat uses two main numbers:

- Current refrigerant temperature

- Saturated refrigerant boiling point

The superheat is how much higher the refrigerant temperature is than its boiling point. For example, if it boils at 40°F and is at 50°F, the superheat is 10°F.

Here are the main steps to measure superheat:

- Use a digital manifold gauge to measure refrigerant pressure

- Find the saturated temperature from the pressure readings

- Check the actual refrigerant temperature at the evaporator outlet

- Subtract the saturated temperature from the actual temperature

Professional HVAC techs use tools like digital manifold gauges and temperature probes. These tools help get superheat measurements right. This keeps the system running smoothly and prevents damage.

“Accurate superheat calculation is the cornerstone of efficient HVAC system maintenance.”

Superheat values can change based on the system, refrigerant, and how it’s used. Always check the manufacturer’s guidelines for the right superheat range for your HVAC system.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopEssential Tools for Superheat Measurement

Measuring superheat in air conditioning needs precision and the right tools. Modern HVAC technicians use advanced tools for better and faster calculations. These tools make hvac refrigerant superheat calculation more precise than ever.

Experts use special equipment to keep systems running well and find problems fast. New tools have made superheat analysis more accurate and easier.

Digital Manifold Gauges

Digital manifold gauges are a big step up in HVAC tech. They offer many benefits:

- Precise digital readings with little error

- Built-in temperature compensation

- Ability to store and compare many readings

- Integrated data logging capabilities

Temperature Probes and Sensors

Getting accurate temperature readings is key for superheat calculations. Modern temperature probes have:

- Rapid response times

- High-precision readings

- Multiple connection options

- Compatibility with various HVAC systems

Smart Tools and Mobile Applications

Technology has changed superheat measurement with smart tools and apps. These tools let technicians:

- Do instant superheat calculations

- Get real-time system diagnostics

- Make detailed reports

- Share data on different platforms

Pro Tip: Always calibrate your measurement tools to ensure the most accurate superheat readings possible.

Using modern tools boosts diagnostic accuracy. It also helps avoid system failures and improves HVAC performance.

Common Superheat Issues and Troubleshooting

Knowing about hvac superheat is key to keeping your cooling system running well. Fixing ac superheat problems can stop system failures and keep it running smoothly.

When you face superheat issues, you’ll see a few common problems. These need careful checking:

- Low Superheat Conditions

- Potential liquid refrigerant entering compressor

- Risk of compressor damage

- Reduced system efficiency

- High Superheat Conditions

- Increased energy consumption

- Potential overheating of compressor

- Reduced cooling capacity

Here are the main steps to fix ac superheat problems:

- Check thermostatic expansion valve (TXV) operation

- Inspect refrigerant charge levels

- Evaluate evaporator coil condition

- Measure suction line temperature

- Verify system superheat readings

“Proper superheat measurement is the key to understanding your HVAC system’s health and performance.” – HVAC Professional

Experts say regular maintenance stops superheat problems. By watching your system’s superheat, you can spot issues early. This saves you from expensive fixes later.

Target Superheat Settings for Different Systems

Knowing the right superheat settings is key for your HVAC system’s best performance. Each type of cooling system needs a specific target superheat. This ensures they work well and last longer.

Choosing the correct superheat settings greatly affects your system’s efficiency and dependability. Let’s look at what different HVAC applications need:

Residential AC Units

Residential air conditioning systems usually need a superheat between 8 to 12 degrees. Important factors include:

- Indoor and outdoor temperatures

- The type of refrigerant used

- The manufacturer’s suggested settings

Commercial HVAC Systems

Commercial systems need more precise superheat control because of their size and complexity. The superheat range is typically 10 to 15 degrees, based on:

- The system’s size and capacity

- Specific needs for the application

- The environment it operates in

Industrial Applications

Industrial refrigeration systems require the most advanced superheat control. They might need superheat settings from 12 to 18 degrees. Key considerations include:

- Precise metering device performance

- The refrigerant’s properties

- Extreme operating conditions

Always check your system’s manufacturer guidelines for the best superheat settings. This is important for your specific HVAC needs.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopRelationship Between Superheat and System Performance

Learning about HVAC superheat is key to knowing how well your cooling system works. Superheat affects your HVAC’s efficiency, impacting its cooling power and energy use.

When technicians do an HVAC refrigerant superheat calculation, they find important info. This info shows how well the system is doing. Keeping superheat right helps the system cool well and avoids breakdowns.

- Superheat affects cooling capacity

- Influences compressor efficiency

- Impacts energy consumption

- Determines system stability

The link between superheat and system performance is complex. High superheat levels can change your HVAC system in big ways:

| Performance Metric | Impact of High Superheat |

|---|---|

| Compressor Capacity | Reduced efficiency |

| Volumetric Efficiency | Decreased performance |

| Coefficient of Performance (COP) | Lower energy efficiency |

By watching and controlling superheat, you can make your HVAC system better. This can save you money on energy and make your equipment last longer. Right superheat levels keep your system cool and reliable.

“Superheat is the key to understanding your HVAC system’s true performance” – HVAC Engineering Professionals

Best Practices for Superheat Charging Methods

Learning the superheat charging method is key to keeping your HVAC system running well. This method needs careful attention and precision when adding refrigerant.

To use the hvac refrigerant superheat calculation correctly, follow these steps:

- Make sure your system is ready before adding refrigerant

- Check the temperature and system load

- Use digital manifold gauges for accurate readings

- Add refrigerant slowly to the suction line

The superheat charging method involves adding refrigerant in vapor form through the compressor’s suction port. This method stops liquid refrigerant from harming the compressor.

Important safety tips include:

- Wear the right protective gear

- Work in areas with good air flow

- Follow the manufacturer’s refrigerant charging instructions

- Use tools that are calibrated

Experts say to keep an eye on superheat values while charging. Being precise is vital for the best system efficiency and avoiding mechanical issues.

Accurate superheat charging protects your HVAC investment and ensures peak system performance.

Keep in mind that different refrigerants might need different charging methods. Always check the manufacturer’s guidelines for your HVAC system. This ensures the best superheat charging method.

Impact of Environmental Conditions on Superheat

Knowing about HVAC superheat means grasping how the environment affects it. Your HVAC system doesn’t work in a vacuum. Temperature, humidity, and seasonal changes greatly affect superheat levels and efficiency.

Environmental factors pose big challenges for keeping HVAC systems at the right superheat. These outside elements can change how the refrigeration cycle works. This means your system needs to be adjusted and watched closely.

Temperature’s Critical Role

Temperature has a big impact on superheat performance. As outside temperatures change, your HVAC system must adjust to keep refrigerant heat transfer right. Important temperature points include:

- Outdoor air temperature affects condenser operation

- Indoor temperature influences evaporator efficiency

- Temperature changes need the system to respond quickly

Humidity’s Significant Impact

Humidity levels are key in superheat calculations. Higher humidity can:

- Boost latent heat load

- Change evaporator performance

- Alter how refrigerant absorbs heat

Seasonal Performance Variations

Seasonal changes need special superheat strategies. Summer’s heat and winter’s cold require different system setups. Experts use special charts to adjust refrigerant charge based on outdoor and indoor temperatures.

“Environmental adaptability defines superior HVAC system performance.” – HVAC Engineering Insights

Understanding these environmental factors helps your HVAC system work at its best in all conditions.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopManufacturer Guidelines and Specifications

It’s key to know the carrier superheat guidelines and trane superheat specs for your HVAC system. Each maker has its own set of rules. These can greatly affect how well your system works and how long it lasts.

When you’re dealing with HVAC systems, check the IOM manual from the maker. This manual has vital info on the superheat needs for your gear.

- Carrier superheat guidelines usually give exact temperature ranges

- Trane superheat specs can change based on the system type and refrigerant

- Always look at the original equipment manufacturer (OEM) manual

Manufacturers create these guidelines for a few reasons:

- To make sure your system works its best

- To keep your warranty valid

- To help you save energy

- To stop damage to your system

Each maker has its own set of rules. These can change based on:

| Factor | Impact on Superheat |

|---|---|

| Refrigerant Type | Directly affects superheat calculation |

| System Application | Home vs. business needs are different |

| Equipment Model | Has special design factors |

By sticking to carrier superheat guidelines and trane superheat specs, you can get the most out of your HVAC system. This helps avoid any problems with how it works.

Conclusion

Knowing what HVAC superheat is key to keeping systems running well. Understanding superheat can make cooling systems last longer and work better. This is true for homes, businesses, and factories.

Managing superheat is more than just checking temperatures. It involves using the right tools and knowing how refrigeration works. By following the tips in this guide, you can avoid system failures and make HVAC systems work better.

It’s important to keep learning and follow the maker’s rules in HVAC. Knowing about superheat helps make systems more reliable and saves energy. This means better cooling and lower costs for repairs and replacements.

As HVAC tech gets better, knowing how to set and measure superheat is more important. Keep learning and be precise to improve your skills. This will help you serve your clients better.