Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How to Recover a Charge in HVAC? Ever wondered how HVAC pros safely remove refrigerant without harming the planet? The skill of hvac refrigerant recovery is more than technical—it’s a big environmental responsibility. It helps protect our planet’s delicate ecosystem.

Since 1987, the Montreal Protocol has made it a must for technicians to follow strict rules when handling refrigerants. Learning to recover a charge in hvac is not just a job requirement. It’s also key to stopping ozone-depleting substances from getting into the atmosphere.

This guide will show you the key techniques, safety steps, and best practices for refrigerant recovery. Whether you’re an experienced HVAC tech or a curious homeowner, knowing these processes is important. It helps protect your equipment and the environment.

Key Takeaways

- Refrigerant recovery is legally mandated to protect the environment

- Proper recovery techniques prevent harmful emissions

- EPA regulations require certified technicians for refrigerant handling

- Recovery methods vary based on system type and refrigerant

- Safety and precision are critical in refrigerant management

Table of Contents

Understanding HVAC Refrigerant Recovery Basics

Recovering refrigerant from AC systems is key for keeping our environment safe and following the law. It needs special knowledge and careful attention to rules.

HVAC maintenance is more than just fixing things. It’s about protecting our planet and following strict rules for handling refrigerants.

What is Refrigerant Recovery?

Refrigerant recovery means taking refrigerant out of an HVAC system without letting it escape into the air. This method includes:

- Collecting refrigerant in a special recovery cylinder

- Keeping the environment clean

- Getting the system ready for maintenance or replacement

Environmental and Legal Importance

Since July 1, 1992, the Clean Air Act has set strict rules for refrigerant handling. Technicians must:

- Get all refrigerant before starting maintenance

- Use EPA-approved recovery tools

- Avoid releasing harmful substances

When Recovery is Necessary

You’ll need to recover refrigerant when:

- Replacing an HVAC system

- Fixing big refrigerant leaks

- Swapping out major parts

- Getting rid of old equipment

Professional HVAC technicians see refrigerant recovery as a technical skill and an environmental duty.

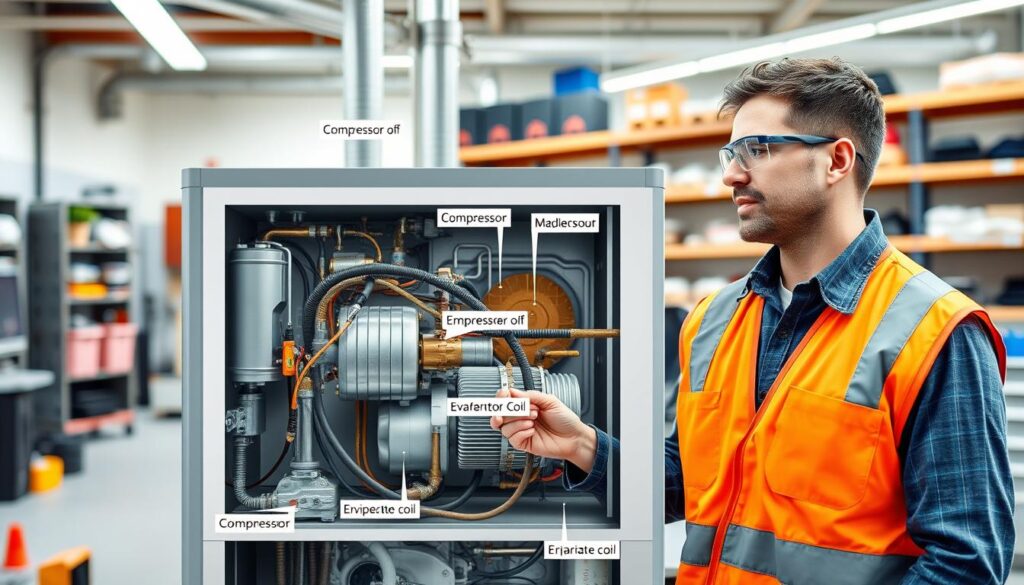

Essential Tools and Equipment for Refrigerant Recovery

Professional HVAC technicians need specific refrigerant recovery equipment for safe and efficient service. Knowing the right tools is key to better recovery procedures and system performance.

For successful refrigerant recovery, you need a set of specialized tools. Your toolkit should have essential pieces for different recovery situations.

- Refrigerant Recovery Machine

- Recovery Cylinders

- Manifold Gauge Set

- Safety Personal Protective Equipment

Choosing the right refrigerant recovery equipment is about understanding system needs. Each refrigerant, like R-410A, requires its own handling and machinery.

| Equipment Type | Primary Function | Recommended Usage |

|---|---|---|

| Recovery Machine | Extract refrigerant | All HVAC systems |

| Recovery Cylinder | Store recovered refrigerant | EPA-certified recycling |

| Manifold Gauge Set | Measure system pressures | Diagnostic procedures |

For proper HVAC charge procedures, invest in top-quality, certified recovery equipment. Look for machines with digital displays, automatic shut-off, and support for various refrigerants.

Professional tip: Always verify your equipment’s certification and maintain it according to manufacturer specifications.

By choosing the right refrigerant recovery equipment, you ensure efficient, safe, and eco-friendly HVAC service.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopSafety Precautions and EPA Compliance Guidelines

Refrigerant recovery is a key process that needs strict safety and environmental rules. It’s important to protect yourself and the environment during the freon recovery process. You need to be well-prepared and know what to do.

Personal Protective Equipment Requirements

Your safety is the top priority when doing ac system recharge steps. You need to wear:

- Chemical-resistant safety glasses with side shields

- Insulated, chemical-resistant gloves

- Long-sleeved protective clothing

- Steel-toed work boots

- Respiratory protection mask

EPA Section 608 Regulations

The Environmental Protection Agency (EPA) has strict rules for refrigerant handling. Technicians must:

- Get EPA certification before handling refrigerants

- Use approved recovery equipment

- Prevent refrigerant releases into the atmosphere

- Keep detailed recovery and disposal records

Environmental Safety Measures

Responsible refrigerant management is more than just personal safety. Preventing environmental contamination is key during freon recovery. Important steps include:

- Checking equipment for leaks before recovery

- Using dedicated recovery cylinders

- Properly storing and disposing of recovered refrigerants

- Minimizing refrigerant exposure to open flames or high temperatures

Remember: Proper safety procedures protect both you and the environment during HVAC refrigerant recovery.

How to Recover a Charge in HVAC

Recovering a charge in an HVAC system needs skill and the right tools. Knowing how to charge your system right is key for keeping it running well and safely.

The recovery steps are important for your equipment and the planet. Learning how to do this right means following a set of steps carefully. This ensures all refrigerant is removed.

- Prepare the recovery machine and necessary tools

- Verify system pressure and temperature

- Connect recovery equipment correctly

- Monitor refrigerant transfer carefully

- Ensure complete refrigerant extraction

Experts use special machines to catch refrigerant without letting it out. These machines work with many refrigerants and systems.

Your recovery steps should always focus on:

- Safety first

- Following environmental rules

- Keeping equipment in good shape

- Managing refrigerant well

Charging your HVAC system right takes focus and knowing about refrigerants. Each time you do it, you need to be ready and do it right. This keeps your system working well and meets environmental rules.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopDirect Recovery Method: Step-by-Step Process

HVAC refrigerant recovery needs careful steps. The direct recovery method is the simplest way for technicians to remove refrigerant safely. By following a set process, you can ensure the system is charged correctly and protect the environment.

Equipment Setup and Connection

Getting ready for refrigerant recovery involves several key steps:

- Choose a recovery machine that’s certified for your refrigerant type

- Check all hoses and connections for leaks or damage

- Make sure the recovery cylinder is clean and suitable for the refrigerant

Recovery Process Monitoring

While recovering refrigerant, you must watch several factors closely:

| Parameter | Critical Range | Action Required |

|---|---|---|

| Pressure | 15-25 PSI | Maintain steady pressure |

| Temperature | 60-75°F | Monitor ambient conditions |

| Recovery Speed | 1-2 lbs per minute | Adjust machine settings |

Completion and System Checks

Once refrigerant is recovered, do some final checks:

- Make sure all refrigerant is removed

- Check the vacuum reading on the recovery machine

- Disconnect the equipment carefully

- Write down the recovery process details

Proper HVAC refrigerant recovery keeps equipment working well and protects the environment. Always focus on safety and accuracy during the process.

Push/Pull Recovery Method for Large Systems

For big AC systems, the push/pull recovery method is key. It’s made for systems with over 15 pounds of refrigerant. This method is quicker and more efficient.

This technique uses pressure differences to pull out refrigerant fast. Technicians control these pressures to get the job done quickly and with less effort.

- Ideal for large HVAC systems

- Faster than traditional recovery methods

- Minimizes refrigerant waste

- Reduces overall ac system recharge steps

Here are important things to think about when using the push/pull method:

- Make sure your equipment fits

- Check if the system’s pressure is right

- Use certified recovery tools

- Follow EPA rules

| Recovery Method | Refrigerant Volume | Efficiency Rate |

|---|---|---|

| Standard Recovery | Under 15 lbs | 70-80% |

| Push/Pull Recovery | Over 15 lbs | 90-95% |

Technicians need to watch the pressure and system conditions closely. Getting the right training and certification is crucial for safe use of this technique.

Liquid Recovery Technique for Efficient Service

Liquid recovery is key in the freon recovery process for HVAC system charging. It’s a special method that lets technicians quickly and accurately remove refrigerant from cooling systems.

Professional HVAC technicians see big benefits in using liquid recovery. It’s different from standard vapor recovery because it focuses on the liquid state of refrigerant. This makes system maintenance faster and more thorough.

Benefits of Liquid Recovery

- Accelerated refrigerant removal process

- Reduced equipment wear and stress

- More efficient for large refrigerant volumes

- Enhanced precision in hvac system charging

System Requirements

Not every HVAC system can use liquid recovery. You need the right equipment and conditions for it to work well:

- Compatible recovery machine

- Proper high-side connection

- Adequate system pressure

- Safe ambient temperature conditions

Implementation Steps

To do liquid recovery right, follow these steps:

- Verify system compatibility

- Connect recovery equipment to high-side service port

- Monitor refrigerant pressure during extraction

- Use appropriate personal protective equipment

Learning liquid recovery can make your HVAC service better. It shows you’re skilled in managing refrigerant.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopTroubleshooting Common Recovery Issues

Recharging HVAC systems can be tricky. Technicians face many challenges that need quick fixes. Knowing how to handle these issues is key.

Common problems can slow down your HVAC work. Spotting these issues fast helps avoid damage. It also keeps refrigerant levels right.

- Slow Recovery Rates: Indicates potential blockages or equipment malfunction

- Incomplete Refrigerant Removal: Suggests contamination or incorrect recovery technique

- Equipment Performance Problems: Reflects maintenance or calibration needs

Here are some important steps for fixing HVAC refrigerant recovery issues:

- Inspect recovery equipment for visible damage

- Check connection points for potential leaks

- Verify system pressure readings

- Clean or replace filters

| Issue | Potential Cause | Recommended Action |

|---|---|---|

| Low Recovery Speed | Clogged filters | Replace recovery machine filters |

| Incomplete Recovery | Incorrect pressure settings | Recalibrate recovery equipment |

| Equipment Malfunction | Worn components | Professional equipment inspection |

Professional tip: Regular maintenance of recovery equipment prevents most troubleshooting scenarios.

For tough HVAC refrigerant recovery problems, get help from a certified tech. Some issues need special tools and expert skills to fix right.

Best Practices for Recovery Speed Optimization

To make hvac refrigerant recovery more efficient, plan carefully and choose the right equipment. Technicians can speed up their work by using specific techniques. These methods cut down on time and boost performance.

Using refrigerant recovery equipment well depends on knowing key strategies. Your method can greatly affect how fast and well you work.

Temperature Management Techniques

Temperature is key in refrigerant recovery speed. Here are some important tips:

- Keep recovery cylinder temperatures between 40-50°F for best results

- Use insulated hoses to avoid temperature changes

- Watch the ambient temperature during recovery

- Use external cooling when needed

Equipment Selection Guidelines

Choosing the right refrigerant recovery equipment is crucial for better efficiency:

- Go for machines with high recovery rates

- Choose equipment that works with many refrigerant types

- Invest in units with digital displays for accurate monitoring

- Consider portable designs for easy use in different places

Pro tip: Shorter hoses and direct connections can cut down recovery time. They reduce resistance and prevent refrigerant loss.

By following these best practices, HVAC pros can make their refrigerant recovery faster and more efficient. They’ll use top-notch refrigerant recovery equipment for better service.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopMaintenance and Storage of Recovery Equipment

Keeping refrigerant recovery equipment in good shape is key. It ensures your tools work well for a long time. HVAC pros should always prioritize their equipment’s care.

Regular upkeep is essential for your equipment’s health:

- Clean external surfaces after each use

- Inspect hoses and connections for wear

- Check electrical components and battery connections

- Verify calibration of pressure gauges

Storing your equipment right is also vital. Here’s how to keep it safe:

- Store in a cool, dry environment

- Use protective cases or covers

- Keep away from direct sunlight

- Disconnect batteries during long-term storage

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| External Cleaning | After Each Use | Prevent Contamination |

| Hose Inspection | Monthly | Ensure Leak-Free Operation |

| Calibration Check | Quarterly | Maintain Accuracy |

Pro tip: Always check your manufacturer’s specific maintenance guidelines for your model.

Following these maintenance and storage tips will help your equipment last longer. It will also work better and meet HVAC standards.

Conclusion

Proper HVAC refrigerant recovery is key for heating and cooling pros. It’s not just a skill—it’s a big responsibility. By learning how to recover refrigerant, you help the environment and keep your reputation strong.

Following the best practices in refrigerant recovery keeps you legal and eco-friendly. It also ensures your systems work at their best. Every step in the recovery process needs care, safety, and technical know-how.

For HVAC techs, managing refrigerant is more than just maintenance. It’s about always learning, following EPA rules, and using the latest recovery methods. This keeps systems running smoothly and efficiently.

As you grow in your HVAC career, remember that refrigerant recovery skills show your true worth. Your hard work and knowledge help the environment and keep cooling systems running well across the U.S.