Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How to Assemble HVAC Duct? Ever wondered why some buildings stay comfy while others have trouble with temperature? It’s all about the HVAC ductwork. Your home’s comfort depends on ducts that spread air well and efficiently.

Assembling HVAC ducts is more than just a job—it’s an art. It needs precision, knowledge, and the right methods. Whether you’re a DIY fan or a pro contractor, knowing how to do it right can boost your indoor air and system performance.

This guide will take you through every important step of installing HVAC ductwork. We’ll make complex tasks simple. This way, your HVAC system will run at its best.

Key Takeaways

- Proper duct assembly is crucial for optimal HVAC performance

- Understanding different ductwork materials enhances installation quality

- Precise measurements prevent air leakage and energy waste

- Safety equipment is essential during ductwork installation

- Professional techniques can significantly improve system efficiency

Table of Contents

Essential Tools and Materials for HVAC Duct Assembly

Starting a DIY duct assembly project needs careful planning and the right tools. Knowing how to connect sheet metal ducts well depends on having the right tools. HVAC pros say quality tools are key to making reliable ductwork.

Basic Sheet Metal Tools Required

For connecting sheet metal ducts, you’ll need special tools for precise cuts and secure connections:

- Tape measure for accurate measurements

- Circular saw for cutting sheet metal

- Hand seamers for forming precise edges

- Right and left hand snips

- Straight bench snips

- Drill with 1/4″ hexhead driver

- Claw hammer for general assembly

“Precision is the key to successful duct assembly.” – HVAC Professional

Safety Equipment and Protective Gear

Safety is crucial during DIY duct assembly. Protect yourself with essential gear:

- Safety glasses

- Work gloves

- Dust mask

- Long-sleeve protective clothing

- Steel-toed boots

Material Selection Guide

Choosing the right materials is key for your HVAC project. Sheet metal ducts offer durability and efficiency, while flexible options are easier to install in tight spaces. Think about:

- Building structure

- Airflow requirements

- Budget constraints

- Long-term performance

Investing in quality tools and understanding material selection will help you succeed in your DIY duct assembly project. You’ll get professional-level results.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopPlanning Your Duct System Layout

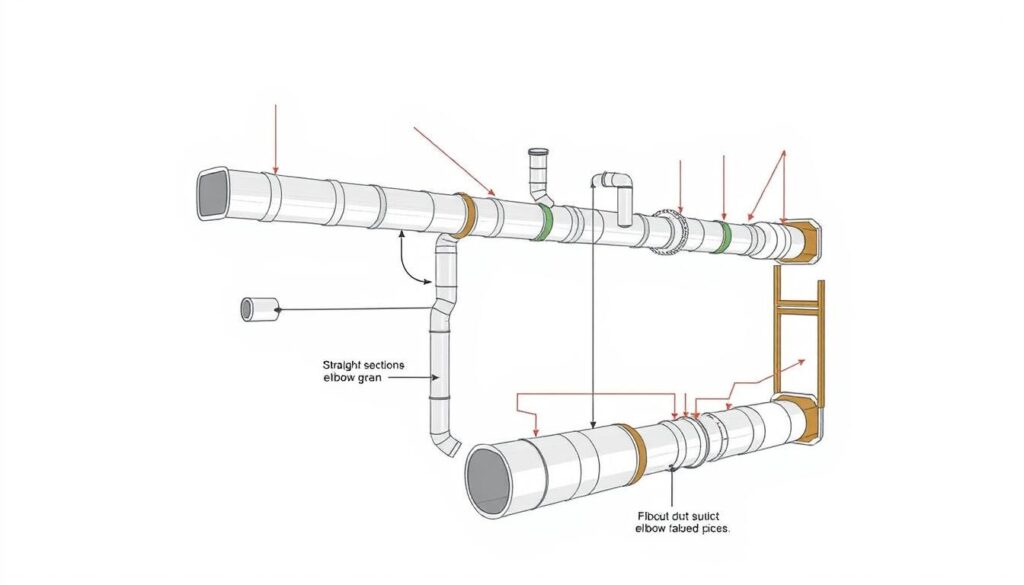

Creating a good HVAC duct system starts with careful planning. Your guide for fitting ducts begins with knowing your space’s needs. Before you start, make a detailed layout for the best airflow and energy use.

For successful air duct installation, consider a few key things:

- Room-by-room heat load calculations

- Precise measurement of living spaces

- Identifying optimal duct path routes

- Determining supply and return register locations

A well-designed duct system depends on knowing your home’s heat needs. Professional HVAC designers suggest making a detailed floor plan for duct routes. This helps cut down energy loss and boosts system performance.

Your layout planning should include:

- Calculating heat gain and loss for each room

- Sketching a comprehensive ductwork diagram

- Selecting appropriate duct sizes based on room requirements

- Identifying potential installation challenges

“A well-planned duct system is the foundation of an efficient HVAC installation.” – HVAC Engineering Professionals

Good planning can cut down installation time and boost system efficiency. Take your time to measure, think about obstacles, and make a detailed plan before starting your duct installation.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopUnderstanding Different Types of HVAC Ductwork

Choosing the right ductwork is key for your HVAC system’s best performance. Different materials have their own benefits. They can greatly affect your home’s air quality and energy use.

Sheet Metal Ducts vs Flexible Fiberglass

There are two main types of ductwork: sheet metal and flexible fiberglass. Each has its own strengths for connecting ducts and system design.

- Sheet Metal Ducts

- Extremely durable

- Resistant to dust accumulation

- Longer lifespan

- Better air quality maintenance

- Flexible Fiberglass Ducts

- Easier installation

- More adaptable to complex spaces

- Lower initial cost

- Potential for increased dust retention

Advantages and Limitations

Knowing the good and bad of each duct type helps you choose wisely for your installation.

| Duct Type | Advantages | Limitations |

|---|---|---|

| Sheet Metal | High durability, smooth airflow | Higher installation costs |

| Flexible Fiberglass | Cost-effective, flexible routing | More maintenance required |

Choosing the Right Size

Picking the right duct size is crucial for good air flow. Undersized ducts restrict airflow, while oversized ones waste energy and cost more to install.

Think about:

- Home square footage

- HVAC system capacity

- Number of rooms

- Ceiling height

Professional HVAC technicians say precise measurements are key for the best system performance.

How to Assemble HVAC Duct: Basic Techniques

Learning to assemble HVAC duct is all about precision and the right steps. DIY duct assembly is easier than you think if you know the basics. The main thing is to work step by step and focus on the details.

To start your DIY duct project, get your workspace ready and gather your tools. The “zipper” method is key for making tight, secure seams in your ductwork.

- Align duct sections carefully

- Use one hand to keep edges close

- Apply downward pressure with your other hand

- Work the seam together like a zipper

“Precision is the secret to professional-looking duct assembly” – HVAC Professional

Different duct materials need different handling. Sheet metal ducts need careful alignment, while flexible ducts require a softer touch. Take your time and make sure each connection is tight and sealed well.

Getting better at assembling HVAC duct takes practice. Start with small sections and move on to more complex ones. Remember, clean, tight seams are key for your HVAC system’s best performance.

- Check alignment before securing

- Use appropriate fastening methods

- Inspect each connection carefully

With patience and practice, you’ll get good at DIY duct assembly. You’ll create a strong and efficient HVAC system for your home.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopProper Duct Connection Methods

Creating strong and secure connections is key when working with HVAC ductwork. The right methods keep your system efficient and leak-free. Knowing how to connect sheet metal ducts is crucial.

Professional HVAC technicians use several methods for strong duct connections. Each method is important for keeping your ductwork system in top shape.

S-Cleats: The Foundation of Secure Connections

S-cleats are vital for connecting sheet metal ducts. These metal fasteners make tight, overlapping connections that stop air leaks.

- Used for longer top and bottom sections of ducts

- Provide a tight, overlapping seal

- Reduce potential air loss and system inefficiency

Drive Installations for Robust Joining

Drives are key for locking duct pieces together. They are installed along the duct’s sides, making a secure mechanical connection that stops separation.

- Position drives along duct edges

- Hammer or press drives into place

- Ensure even and consistent installation

Draw Band Connectors for Butt Joints

Draw band connectors are great for end-to-end duct connections. They wrap around butt joints, making a tight and seamless connection.

By learning these techniques, you’ll make your HVAC system more efficient and reliable. It will perform at its best.

Installing Supply and Return Air Systems

Installing supply and return air systems right is key for your home’s comfort. The right placement and size of air ducts matter a lot.

When setting up your HVAC, remember these important points for supply and return air systems:

- Supply outlets should spread air evenly in each room

- Return air inlets need to be placed for best air flow

- Make sure there’s enough space between supply and return registers

In multi-level homes, vertical air distribution is very important. Put return registers at the top to stop hot air from staying. This helps keep your home’s temperature even.

“Effective air distribution is the secret to maintaining consistent comfort in any home.” – HVAC Professional

Basements and ground floors need extra care. Make sure there’s enough room around registers and follow air duct installation steps to avoid blockages.

- Supply registers should be at least 6 inches from walls

- Don’t block registers with furniture

- Seal all connections to stop air leaks

Picking the right size and spot for your systems will make your HVAC work better and save energy.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopDuctwork Sealing Techniques

Sealing your HVAC ducts right is key. Good sealing boosts your system’s performance and saves energy. Leaky ducts can lose up to 20% of your heating and cooling energy. So, getting your ducts sealed by pros is a must.

Professional HVAC techs use several methods to make duct connections airtight:

Mastic Application Methods

Mastic sealant is a strong, flexible choice for sealing ducts. It’s great for:

- Sealing odd-shaped gaps and joints

- Stopping air leaks in complex ducts

- Making air-tight connections that last

Metal-Backed Tape Usage

Here’s how to use metal-backed tape for duct sealing:

- Clean the area well before you start

- Stick the tape to smooth, dry surfaces

- Press hard to make sure it sticks

- Choose top-notch foil tape made for HVAC

Quality Control Checks

To check if your ducts are sealed right, do these:

- Look over all joints and seams

- Use a smoke pencil to find leaks

- Do pressure tests on sealed parts

Pro tip: Always wear protective gloves and eye protection when applying sealants and working on ducts.

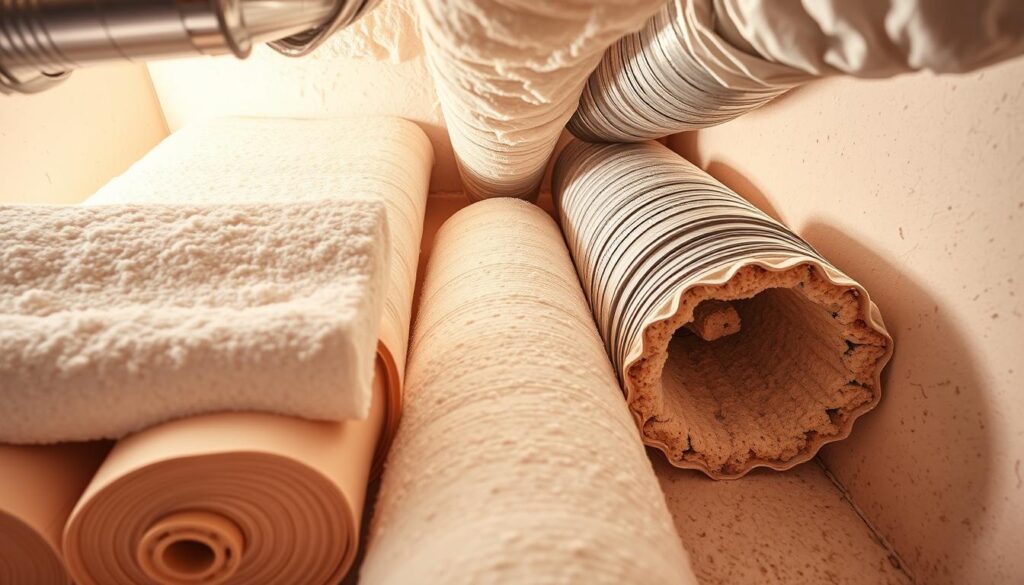

Insulation and Noise Control Solutions

When you’re doing your own duct assembly, insulation is key. It keeps your energy use down and your home comfy. Your HVAC ductwork needs the right insulation to stop heat loss and cut down on noise.

There are many insulation types for your ductwork:

- Fiberglass blanket insulation: It’s cheap and simple to put in

- Foam board: It’s great at keeping heat out

- Spray foam: It makes a solid, protective layer

Choosing the right insulation thickness depends on your area’s climate and where your ducts are. Exterior ducts need thicker insulation than interior ones.

| Insulation Type | R-Value | Best Used For |

|---|---|---|

| Fiberglass Blanket | R-4 to R-8 | Interior wall cavities |

| Foam Board | R-5 to R-10 | Unconditioned spaces |

| Spray Foam | R-6 to R-7 per inch | Challenging access areas |

To reduce noise, think about using acoustic duct liners and sound attenuators. These tools help block sound through your ductwork. This makes your home quieter.

Pro tip: Always wear protective gear and follow manufacturer guidelines when installing ductwork insulation.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopSystem Testing and Airflow Verification

After finishing your air duct installation, it’s time for system testing. This step is key to ensure your HVAC works well. It helps spot any problems and keeps your ductwork running smoothly.

The HVAC duct fitting guide stresses the importance of thorough testing. Airflow checks are essential. Homeowners and technicians must follow these steps carefully.

Measuring Air Distribution

To check your HVAC’s performance, you’ll need to:

- Use a digital airflow meter to check cubic feet per minute (CFM)

- Measure static pressure at key connection points

- Verify airflow across different rooms and zones

- Compare measured airflow against system design specifications

Common Issues and Solutions

When testing, you might find a few issues:

- Uneven airflow: Adjust dampers or check for blockages

- Pressure imbalances: Inspect duct connections and seals

- Temperature inconsistencies: Evaluate insulation and system design

Final Inspection Points

Your final check should include:

- Verifying all connections are secure

- Checking for air leaks

- Ensuring proper system calibration

- Confirming compliance with local building codes

By following these steps, you’ll have a reliable and efficient HVAC system. It will keep your space comfortable all the time.

Conclusion

Assembling HVAC ductwork needs precision, skill, and attention to detail. You’ve learned how to make an efficient ventilation system from this guide. The techniques and methods will help you handle the complexities of installation confidently.

Your success comes from good preparation, choosing the right materials, and using the right connection techniques. You’ve learned about different duct types, sealing, and insulation. Each step is important for a high-performance HVAC system that improves air quality and saves energy.

Keeping your ductwork in good shape is crucial. Make sure to inspect and clean your system every year. Check for leaks, ensure sealing, and verify airflow. These steps will keep your HVAC system running well and your air quality high for years.

Now, you’re ready to take on HVAC duct assembly projects with expert skills. Remember, patience, precision, and learning are key. They will help you create a reliable and efficient ventilation system.