Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How Much Does a HVAC Compressor Weigh? Ever thought about what makes an HVAC compressor heavy and why it’s important? Knowing the weight of an HVAC compressor is key for homeowners, technicians, and HVAC pros. It helps them keep or swap out their cooling gear right.

The weight of an HVAC compressor changes a lot. It depends on the system type, size, and use. Home units are way different from big commercial or industrial ones.

This guide dives into the world of HVAC compressors. We’ll look at weight details, important points, and tips for choosing the right cooling setup.

Key Takeaways

- HVAC compressor weights range from 50 to 500 pounds depending on system type

- Weight impacts installation, transportation, and maintenance requirements

- Different compressor types have unique weight characteristics

- Understanding compressor weight helps prevent possible installation issues

- Getting a pro’s opinion is best for accurate weight checks

Table of Contents

Understanding HVAC Compressor Types and Their Weight Variations

Exploring HVAC compressor specs reveals a wide range of types. Each type affects system performance and weight. Knowing these differences helps you choose the right heating and cooling equipment.

HVAC compressors vary in design, each with its own strengths. These differences impact their size and how well they work.

Single Phase Compressors

Single phase compressors are common in homes. They have several benefits:

- Lighter weight design

- Lower power consumption

- Ideal for smaller living spaces

- Cost-effective solution for home cooling

Three Phase Compressors

Three phase compressors are for bigger spaces like offices and factories. They offer:

- Heavier construction

- Higher power output

- More efficient energy conversion

- Suitable for large-scale cooling systems

Scroll Compressors

Scroll compressors are a newer technology. They bring unique advantages:

- Compact and efficient design

- Reduced noise levels

- Smoother operational performance

- Intermediate weight range between single and three phase models

Your choice of compressor depends on your cooling needs, space, and budget.

Factors Affecting HVAC Compressor Weight

Understanding the weight of an HVAC compressor involves exploring multiple critical factors. The weight of your compressor isn’t random. It depends on several key elements that greatly affect its mass and performance.

The main factor affecting HVAC compressor tonnage is its capacity. Different sizes of compressors have varying weights. Larger units for commercial or industrial use weigh more than smaller ones for homes.

- Compressor capacity measured in BTUs

- Refrigerant type used in the system

- Construction materials

- Additional protective components

Materials are key in determining an HVAC compressor’s weight. Manufacturers choose metals and alloys that balance durability, heat resistance, and weight. Aluminum and copper components add to the mass but ensure efficient heat transfer and reliability.

Refrigerant type also affects compressor weight. Different refrigerants need different structural supports and mechanisms. Modern systems with eco-friendly refrigerants might have special components that change the unit’s total weight.

When looking at HVAC compressor tonnage, consider the balance between performance and design. Your specific needs will help find the right weight and capacity for your cooling system.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopHow Much Does a HVAC Compressor Weigh

Knowing the weight of HVAC compressors is key for both pros and homeowners. The weight changes a lot based on its use and size. Let’s look at the weight ranges for homes, businesses, and big industrial sites.

The weight of an HVAC compressor can vary a lot. It depends on the system’s type and size. This weight affects how easy it is to move, install, and how well it works.

Residential Compressor Weights

Residential HVAC compressors are generally lighter. They’re made for cooling homes and have certain features:

- Weight range: 100 to 300 pounds

- Capacity: 1.5 to 5 tons

- Compact design for easier installation

Commercial Compressor Weights

Commercial HVAC systems need stronger compressors for bigger spaces and complex cooling. Their weight shows their bigger abilities:

| System Type | Weight Range | Typical Capacity |

|---|---|---|

| Medium Commercial | 300-700 pounds | 10-15 tons |

| Large Commercial | 700-1,500 pounds | 15-25 tons |

Industrial Compressor Weights

Industrial HVAC compressors are the heaviest. They’re for huge cooling needs in factories, warehouses, and big buildings:

- Weight range: 1,500 to 5,000+ pounds

- Capacity: 25 tons and above

- Specialized engineering for extreme cooling demands

*Pro Tip*: Always consult a professional when selecting or replacing an HVAC compressor to ensure proper weight and capacity for your specific needs.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopHVAC Compressor Dimensions and Size Specifications

Knowing the exact size of an HVAC compressor is key for a good install and system work. Different sizes can change how well your system cools or heats and how much space it takes up.

There are many sizes of HVAC compressors for homes and businesses. The right size depends on your space and system needs. Important things to think about include:

- Height range for typical compressors

- Width specifications

- Depth measurements

- Weight considerations

Residential HVAC compressors usually have these sizes:

| Compressor Type | Height (inches) | Width (inches) | Depth (inches) |

|---|---|---|---|

| Small Residential | 24-30 | 20-26 | 15-20 |

| Medium Residential | 30-36 | 26-32 | 20-26 |

| Large Residential | 36-42 | 32-38 | 26-32 |

When picking a compressor, make sure to measure your space well. Getting the right size ensures a good fit and system performance. Commercial and industrial compressors are much bigger than home units.

HVAC experts say to always check the exact size with the maker before buying or installing a compressor.

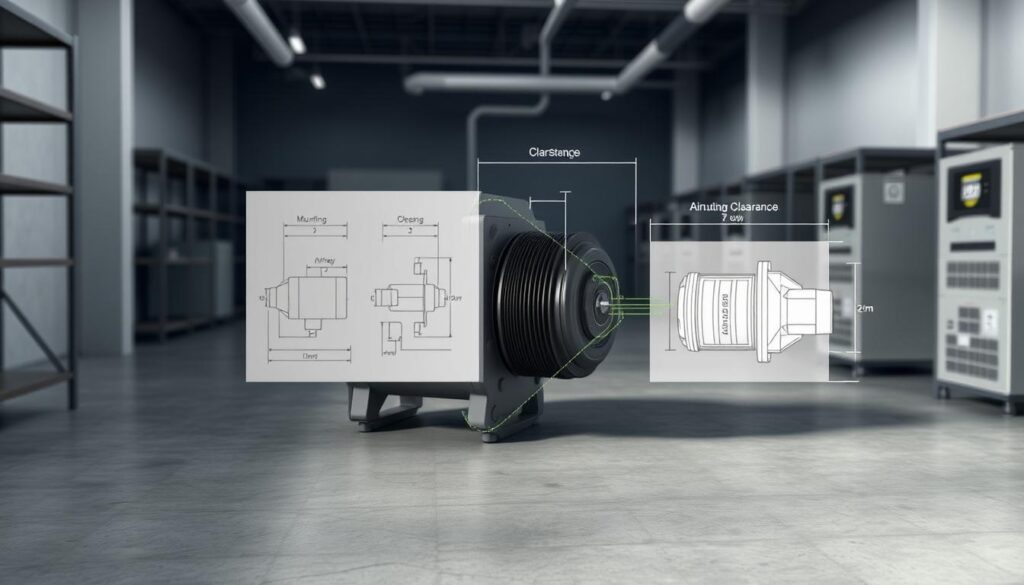

Compressor Capacity and Its Relationship to Weight

It’s important to know how HVAC compressor tonnage and weight are connected. This knowledge helps pick the right system for your space. The compressor’s capacity affects its size and how it works.

The size of the compressor affects its weight. Bigger systems need stronger parts. This makes the compressor heavier.

BTU Ratings and Weight Correlation

Compressor capacity is measured in British Thermal Units (BTU). The link between BTU and weight is not straightforward. Yet, there are clear patterns:

- Smaller residential units: 14,000-24,000 BTU

- Mid-range commercial units: 24,000-60,000 BTU

- Large industrial systems: 60,000-385,000 BTU

Tonnage Impact on Weight

In HVAC, one ton of cooling is 12,000 BTU per hour. As tonnage goes up, so does the compressor’s weight:

| Tonnage | Typical Weight Range | Common Applications |

|---|---|---|

| 1-2 Tons | 100-200 lbs | Small residential spaces |

| 3-5 Tons | 200-400 lbs | Medium-sized homes |

| 5-10 Tons | 400-800 lbs | Commercial buildings |

Flow Rate Considerations

The compressor’s flow rate affects its design and weight. Higher flow rates need bigger parts. This makes the compressor heavier. HVAC experts balance flow rate, BTU, and weight for the best performance.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopInstallation Requirements Based on Compressor Weight

When you plan to install an HVAC compressor, its weight is key. Different weights need different installation plans for safety and best performance.

Several weight-related factors will guide your installation process:

- Structural support needs

- Lifting and moving tools

- Preparation of the mounting area

- Keeping safety in mind

For smaller residential compressors, simple mounting methods usually work. These units weigh between 50-150 pounds, making installation easier.

But, installing commercial and industrial compressors is more challenging. They are heavier and need:

- Special rigging tools

- Strong mounting platforms

- Teams of experts for installation

- Accurate weight calculations

| Compressor Type | Typical Weight Range | Installation Complexity |

|---|---|---|

| Residential | 50-150 lbs | Low |

| Commercial | 150-500 lbs | Medium |

| Industrial | 500-1000+ lbs | High |

Always talk to professional HVAC techs for safe and proper compressor installation. Good planning avoids damage and keeps your system running well for years.

Weight Considerations for Replacement Projects

When planning an HVAC compressor replacement, understanding weight dynamics is key. Your project needs careful evaluation of several factors. This ensures a smooth installation and the best system performance.

Replacing an HVAC compressor requires careful planning and precise execution. The weight of your new compressor affects transportation, installation, and system compatibility.

Handling and Transportation Guidelines

Proper handling of an HVAC compressor is vital to avoid damage and ensure safe installation. Here are some important guidelines:

- Use specialized lifting equipment for compressors over 100 pounds

- Check truck and personnel weight capacity before moving

- Use secure strapping during transit

- Wear proper personal protective equipment

Equipment Required for Installation

Different compressor weights need specific installation equipment. Your project might need:

| Compressor Weight Range | Recommended Equipment |

|---|---|

| 50-100 lbs | Heavy-duty hand truck, 2-person team |

| 100-250 lbs | Hydraulic lift, crane assistance |

| 250+ lbs | Professional rigging team, industrial crane |

“Proper preparation prevents poor performance in HVAC compressor replacement.” – HVAC Industry Professionals

Professional tip: Always check manufacturer specs and consider hiring pros for complex projects.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopMaintenance Impact on HVAC Compressor Weight

Your HVAC compressor’s maintenance is key to its performance and weight. Even though the base weight stays the same, regular upkeep can slightly change the compressor’s effective weight.

During maintenance, several things can affect the weight:

- Accumulation of dust and debris

- Refrigerant charge modifications

- Component replacements

- Lubrication system updates

Experts say tracking these weight changes is vital, more so for rooftop setups or places where weight matters. Regular checks help avoid sudden weight changes that could harm the system’s balance.

“Consistent maintenance isn’t just about performance—it’s about understanding your system’s evolving characteristics.” – HVAC Engineering Professionals

Here are some smart ways to handle HVAC compressor maintenance:

- Keep a record of each maintenance step

- Check the system’s weight before and after service

- Monitor refrigerant levels carefully

- Look over mounting hardware for wear

| Maintenance Activity | Potential Weight Impact |

|---|---|

| Debris Cleaning | Minimal weight reduction |

| Refrigerant Recharge | Slight weight increase |

| Component Replacement | Variable weight changes |

Proactive maintenance keeps your HVAC compressor running well, reliable, and within the expected weight range.

Weight Variations Across Different Manufacturers

Knowing the weight of HVAC compressors from different makers helps you choose the right heating and cooling systems. Each brand has its own design, affecting the weight and how well it works.

Looking at HVAC compressor specs, you’ll see big differences between top brands. Companies like Copeland, Trane, and Carrier make compressors that are unique in weight and performance.

Popular Brands and Their Weight Characteristics

- Copeland: Known for lightweight, efficient scroll compressors

- Trane: Produces robust compressors with durable construction

- Carrier: Offers balanced weight-to-performance ratio designs

Industry Weight Standards

HVAC compressor specs usually follow set weight ranges based on size and use. Home units weigh 50-150 pounds, while big commercial ones can be 200-500 pounds. This depends on their design and needs.

The weight of an HVAC compressor is not just about mass, but about the engineering behind its construction and performance capabilities.

Manufacturers decide on compressor weight by looking at several key things:

- Materials used in construction

- Cooling system design

- Internal component complexity

- Intended performance specifications

When picking an HVAC compressor, think about how weight changes might affect setup, moving it, and system efficiency over time. Your specific needs will help you choose the best brand and model.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopSafety Considerations When Handling Heavy Compressors

When you’re installing or replacing HVAC compressors, safety comes first. Heavy compressors can be dangerous if not handled right. They can cause serious injuries or damage to equipment.

It’s vital to follow safety rules during hvac compressor replacement. Before starting, make sure you have the right safety steps:

- Wear the right personal protective equipment (PPE)

- Use mechanical lifting tools for heavy compressors

- Work with a trained partner during installation

- Check the equipment and work area before starting

The weight of HVAC compressors can vary a lot. This makes team lifting essential. You might need special tools like:

- Hydraulic lifts

- Overhead cranes

- Heavy-duty rolling platforms

- Special HVAC handling dollies

Safety starts with knowing your equipment’s weight and how to handle it. HVAC pros say doing a detailed check before installing is key to avoid accidents.

Always put personal safety first when dealing with heavy HVAC gear.

Ignoring safety can lead to injuries, damage, and expensive fixes. By sticking to safety rules, you keep yourself, your team, and your HVAC systems safe.

Conclusion

Knowing about HVAC compressor weight is key for keeping systems running well. You’ve learned a lot about compressor specs, from homes to big buildings. This knowledge helps when fixing or replacing HVAC systems.

Understanding compressor weights helps you see how they work. Each type has its own weight that affects how it performs. Knowing this helps avoid problems during installation and keeps systems running smoothly.

Both pros and DIYers can use this info to their advantage. Knowing about weight helps fix HVAC systems better. It lets you make smarter choices about your heating and cooling systems.

As HVAC tech gets better, knowing about compressors is more important than ever. You’re now ready to tackle maintenance and repairs with confidence. This knowledge will help you make better choices for your systems.