Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

How Do Chilled Water HVAC Systems Work? Did you know that chillers cool about 75% of commercial buildings? Chilled water HVAC systems are a smart way to manage temperatures. They are more advanced than old cooling methods.

These systems use water to move heat, making them more efficient than air-based cooling. Unlike regular air conditioners, they use chilled water in pipes. This water absorbs heat from inside, keeping temperatures steady and accurate.

Today, many buildings use these systems. They work well in big commercial places and even in places like data centers. Chilled water HVAC systems are reliable and save energy.

Key Takeaways

- Chilled water systems cool about 75% of commercial properties

- Water is used as the primary heat transfer medium

- Provides more consistent and precise temperature control

- Suitable for various building types and sizes

- More energy-efficient compared to traditional cooling methods

Table of Contents

Understanding Chilled Water HVAC System Fundamentals

Chilled water systems are a smart way to cool big places. They’ve been used in commercial and industrial areas for decades. This method has changed how we manage temperatures in large buildings.

Water is great at cooling because it can absorb a lot of heat. It’s 20 times better than air at this. This makes chillers very effective at cooling down spaces.

Basic Principles of Water-Based Cooling

Chilled water systems cool by transferring heat and controlling temperatures. They have a few key features:

- Closed-loop water circulation

- Heat absorption from indoor spaces

- Water temperature reduction to approximately 40 degrees

- Efficient heat dispersion outside the building

Key Components Overview

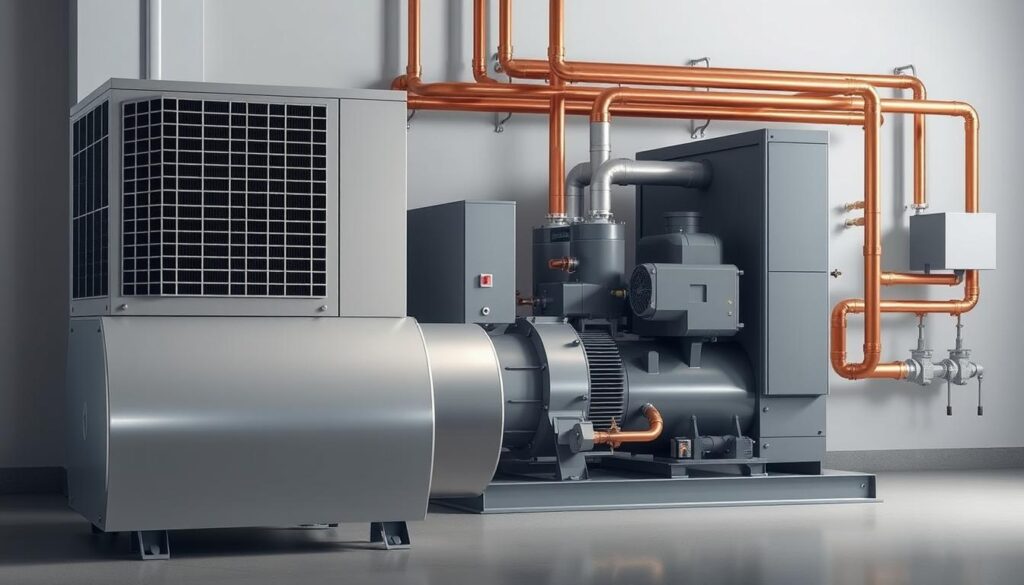

The main parts of a chilled water HVAC system are:

- Chillers: Primary cooling units

- Water pumps: Circulating cooling water

- Cooling towers: Facilitating heat rejection

- Air handlers: Distributing cooled air

System Operation Basics

Water pumps move chilled water through a network. They take heat from inside. The system turns on only when it’s really hot, saving a lot of energy.

Water-chilled cooling systems offer unparalleled flexibility and efficiency in temperature management.

These systems are mainly used in big buildings like hospitals, universities, and data centers. They provide a smart way to control the climate in large areas.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopHow Do Chilled Water HVAC Systems Work

Learning about the refrigeration cycle helps you understand how chilled water HVAC systems cool your space. These systems use thermal energy transfer to make indoor areas comfortable in different buildings.

The cooling process starts with several steps. These steps turn warm indoor air into cool water. Water is key in this cooling strategy.

- Water enters the system at ambient temperature

- Refrigerant absorbs heat from the water in the evaporator

- Chilled water circulates through climate-controlled spaces

- Heat is effectively removed from the indoor environment

Chilled water systems keep temperatures steady. Water’s ability to conduct heat makes it better than air for cooling. Thermal energy transfer occurs seamlessly, cooling quickly and efficiently.

Precise temperature control is the hallmark of advanced chilled water HVAC systems.

| System Component | Primary Function |

|---|---|

| Evaporator | Absorbs heat from water |

| Compressor | Circulates refrigerant |

| Condenser | Releases absorbed heat |

Your chilled water HVAC system turns warm air into cool comfort through a complex refrigeration cycle. By understanding these basic principles, you can see the engineering genius behind modern climate control.

The Role of Chillers in Commercial Buildings

Chilled water systems are key in managing cooling in commercial spaces. They offer efficient temperature control for large areas. This is great for many types of buildings.

Commercial buildings use chilled water systems to keep temperatures right. They also save energy. These systems work well in many places, from big factories to hotels.

Types of Buildings Using Chilled Water Systems

- Hotels and resorts

- Hospitals and medical centers

- Educational institutions

- Manufacturing plants

- Sports venues

- Warehouses

- Office complexes

Benefits for Large-Scale Applications

Commercial chillers are great for cooling big buildings. They control temperature well and use less energy than old systems.

| Chiller Type | Efficiency | Typical Lifespan |

|---|---|---|

| Water-Cooled Chillers | High efficiency | 20+ years |

| Air-Cooled Chillers | Moderate efficiency | 15 years |

Integration with Existing Infrastructure

Modern chilled water systems fit well with current building setups. Absorption chillers are good when you have waste heat. They cool efficiently and cut down on costs.

Efficient chiller operation can lead to up to 30% greater energy savings compared to conventional air conditioning systems.

Using the latest chiller tech can make your building cooler and greener. It also saves money on upkeep over time.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopComponents of the Refrigeration Cycle

It’s important to know how air handling units and chillers work. They use a complex process with four main parts. These parts change the refrigerant and move heat from one place to another.

The refrigeration cycle has four key stages for cooling in HVAC systems:

- Evaporation: Refrigerant takes heat from the cooled water system

- Compression: The compressor raises the refrigerant’s pressure and temperature

- Condensation: Heat is given off to the outside

- Expansion: Refrigerant pressure goes down, ready for the next step

Each part is essential for chiller operation. The compressor is the heart, moving refrigerant through different pressures. It turns low-pressure vapor into high-pressure, hot gas for efficient heat transfer.

“The refrigeration cycle is a sophisticated dance of pressure, temperature, and heat transfer” – HVAC Engineering Insights

Different compressors fit different chiller designs:

- Reciprocating compressors

- Centrifugal compressors

- Screw compressors

Air handling units work well with these refrigeration parts. They spread cooled air in commercial and industrial areas. Knowing this cycle shows the advanced engineering in cooling systems today.

Water Distribution and Heat Transfer Process

Chilled water systems keep indoor spaces cool and comfy. They use a network of water loops to spread cool air around buildings.

The cooling process depends on detailed water systems. These systems control temperature and heat exchange well.

Primary and Secondary Water Loops

Chilled water systems have two main water loops:

- Primary loop: Goes straight to the chiller

- Secondary loop: Sends cooled water to different parts of the building

Heat Exchange Mechanisms

Heat transfer happens through special heat exchangers. These parts help cool spaces efficiently and control temperature well.

- They remove heat from inside spaces

- They keep temperatures just right

- They use less energy

Temperature Control Systems

Advanced systems watch and adjust water temperatures. This keeps places comfortable.

Good hydronic cooling systems can cut energy use by up to 40% compared to old HVAC systems.

| System Component | Primary Function | Temperature Range |

|---|---|---|

| Chilled Water Pump | Water Circulation | 35.6°F – 44.6°F |

| Heat Exchanger | Thermal Energy Transfer | Varies by Application |

| Temperature Sensor | Monitoring and Control | Precise Regulation |

Hydronic cooling systems use smart water and heat processes. They manage temperature well and save energy in many places.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopCooling Towers and Heat Rejection

Cooling towers are key to keeping your HVAC system efficient. They help make cool water for your system to work better. This makes your cooling system run at its best.

Cooling towers work by cooling water through evaporation. Warm water from the chiller is sprayed into tiny droplets. This increases the surface area for heat to be released. This method cools the water more than air-cooled systems.

“Cooling towers are the unsung heroes of thermal management, transforming hot water into a cool, efficient energy solution.”

Here are some benefits of cooling towers:

- They make your system more energy-efficient

- They use less electricity

- They lower your costs

- They handle heat better

Here are some stats on cooling towers:

- Water-cooled chillers use up to 50% less electricity than air-cooled ones

- Keeping them well-maintained can save a lot of energy

- They can cut down water and energy use a lot

Keeping your cooling tower in good shape is important. Regular water treatment and checking for impurities are key. This helps your system work better and last longer.

Using cooling tower technology wisely can make your HVAC system more eco-friendly and cost-effective. It’s a smart way to manage heat.

Energy Efficiency and System Performance

Chilled water HVAC systems are key to saving energy in commercial buildings. HVAC systems use about 40% of all energy. So, it’s important for managers and engineers to know how to make them more efficient.

Optimization Strategies for Cooling Load Management

To make chilled water systems more efficient, we need a few key steps. These include:

- Using advanced control algorithms

- Installing Variable Frequency Drives (VFDs)

- Keeping an eye on system performance with analytics software

- Doing regular maintenance and calibration

Cost-Saving Measures

Lowering the cooling load can save a lot of money. Here are some ways to do it:

| Strategy | Potential Energy Savings |

|---|---|

| Ductwork Sealing | Up to 20% efficiency improvement |

| Equipment Upgrades | 30% reduction in energy consumption |

| Preventive Maintenance | Prevents costly system breakdowns |

Environmental Impact

Today’s chilled water systems are very energy-efficient. A top-notch chiller can cool almost 22 kW of space for every 1 kW of electricity. This means less carbon emissions and greener buildings.

“Optimizing HVAC systems is not just about cost savings, but about creating more sustainable and efficient building environments.”

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopCommon Maintenance Requirements

Keeping your chilled water HVAC system in top shape is key. It ensures your chiller works well and your water pumps last longer. Regular upkeep stops sudden failures and keeps energy use low.

Effective maintenance includes several important steps:

- Daily visual inspections of system components

- Weekly checks of critical system parameters

- Semi-annual load balance assessments

- Annual complete system tune-ups

Some critical maintenance tasks are:

- Chemical water treatment to stop corrosion

- Cleaning of cooling tower parts

- Refrigerant level checks

- Electrical system inspections

“Preventive maintenance can cut energy use by up to 20% in HVAC systems” – US Department of Energy

| Maintenance Frequency | Key Actions | Expected Benefit |

|---|---|---|

| Daily | Visual system check | Early issue detection |

| Weekly | Coil and leak inspection | Prevent performance drop |

| Annually | Comprehensive system tune-up | Optimize chiller operation |

Remote monitoring systems can now automate diagnostic insights, reducing manual logging and improving overall system efficiency.

By sticking to these maintenance tips, you’ll get the most out of your chilled water HVAC system. You’ll cut down on unexpected downtime and save on energy costs.

Conclusion

Chilled water HVAC systems are more than just air conditioning. They use water to cool, making them very efficient. This is great for big buildings where keeping the temperature right is key.

Getting a chilled water HVAC system is a smart move for your building. It saves energy, cuts down on costs, and is better for the planet. Even though it costs a lot upfront, it’s worth it for the long-term benefits.

Keeping your system in top shape is important. Regular checks, clean water, and looking after parts help it work its best. These systems are leading the way in cooling technology for big buildings.

The future of keeping buildings cool is looking bright. With hydronic cooling systems, you’re choosing a green way to keep your space comfy. It’s not just about cooling; it’s about doing it in a way that’s good for the planet.