Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

Do It Yourself HVAC Ductwork? Installing HVAC ductwork might look hard, but with the right help, it can be a DIY project. This guide will teach you how to make an efficient air system.

Are you tired of the high costs of professional HVAC ductwork installation? What if you could do it yourself and improve your home’s air flow?

If you love DIY or want to save money, learning about ductwork is key. It lets you get professional results and better air quality at home.

Key Takeaways

- Learn the basics of HVAC ductwork installation

- Save money by doing it yourself

- Boost your home’s air flow and efficiency

- Gain confidence in DIY skills

- Know important safety and technical tips

Table of Contents

Understanding HVAC Ductwork Basics

Your home’s HVAC system uses ductwork to move air around. Knowing about ductwork replacement helps keep your home comfy and energy-smart.

Ductwork is like your home’s air highway. It carries air from your HVAC to every room. This keeps the temperature and air quality even.

Types of Air Ducts and Materials

When fixing your HVAC ducts, you’ll find a few main types:

- Rigid Metal Ducts: These are strong and let air flow smoothly, made from steel or aluminum.

- Flexible Ducts: They’re light and simple to put in, great for small spaces.

- Fiberboard Ducts: Made from fiberglass with a foil layer, they’re a good choice too.

Key Components of Ductwork Systems

A good ductwork system has a few key parts:

| Component | Function |

|---|---|

| Supply Plenum | Sends cooled or heated air from the HVAC unit. |

| Return Plenum | Gets air to send back to the HVAC for heating or cooling. |

| Registers | Let air into your rooms. |

Benefits of Proper Ductwork Installation

Getting your ductwork right has many perks:

- It makes your home more energy-efficient.

- It improves the air you breathe inside.

- It keeps the temperature even in all rooms.

- It can lower your energy bills.

Good ductwork design and care can really make your home more comfortable and save energy.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

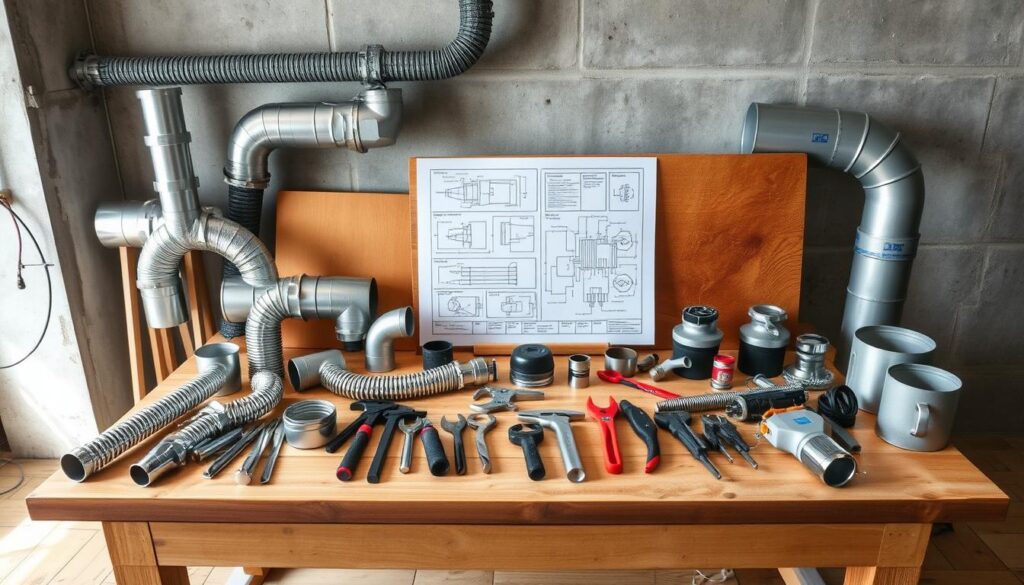

Visit the ShopEssential Tools and Materials for DIY Installation

Getting ready for air duct work means picking the right tools and materials. The success of your HVAC system retrofit depends on the tools you use. Using professional-grade tools can greatly improve your installation’s quality and efficiency.

Before starting your ductwork project, make sure you have these key tools:

- Measuring and Marking Tools

- Tape measure

- Permanent marker

- Chalk line

- Cutting Tools

- Circular saw

- Reciprocating saw

- Metal snips

- Fastening and Shaping Tools

- Drill with multiple bits

- Hand seamers

- Barfold tool

Always put safety first when working on air ducts. Good protective gear is key to avoiding injuries and making the installation go smoothly.

| Category | Recommended Materials | Purpose |

|---|---|---|

| Duct Materials | Galvanized steel | Durable main ductwork |

| Insulation | Fiberglass wrap | Thermal efficiency |

| Sealants | Mastic sealant | Prevent air leaks |

| Fasteners | Sheet metal screws | Secure duct connections |

Your HVAC retrofit needs precision and the right tools. By choosing quality tools and knowing how to use them, you’ll build a strong and efficient ductwork system. This will make your home more comfortable and save energy.

Planning Your Ductwork Layout

Creating a good ductwork layout is key for your HVAC system. It needs careful planning to ensure good airflow and temperature. This is important for your home’s comfort.

Measuring and Calculating Duct Sizes

Getting the right duct sizes is essential. Start by making a detailed floor plan of your home. Note:

- Room dimensions

- Ceiling heights

- Existing structural elements

- Potential obstruction points

Creating an Efficient Air Distribution Plan

To plan air distribution well, consider these points:

- Calculate total square footage of living space

- Determine BTU requirements per room

- Select appropriate duct sizes based on airflow needs

| Room Type | Recommended Duct Size | Airflow Requirement |

|---|---|---|

| Bedroom | 6″ – 8″ | 100-150 CFM |

| Living Room | 10″ – 12″ | 250-350 CFM |

| Kitchen | 8″ – 10″ | 150-250 CFM |

Identifying Optimal Register Locations

Choosing the right spot for registers is crucial. Avoid placing registers directly under windows or near doors to prevent energy loss. This helps keep the temperature steady.

Pro tip: Use load calculation software or get help from HVAC experts. They can help make your ductwork plan better for your home’s needs.

Do It Yourself HVAC Ductwork: Step-by-Step Process

Trying to do your own HVAC ductwork might seem tough. But, with the right steps and preparation, you can do it. It’s all about knowing each step and getting ready well.

First, collect all the tools and materials you need. You’ll require:

- Measuring tape

- Metal cutting tools

- Protective gloves

- Duct sealant

- Support straps

The installation process has several important steps:

- Measure and plan your duct layout carefully

- Cut ducts to precise specifications

- Secure connections with proper fasteners

- Seal all joints and connections

- Install support brackets

Pro tip: Always wear protective gear and work methodically to ensure a professional-quality installation.

| Installation Stage | Key Actions | Time Estimate |

|---|---|---|

| Preparation | Measure space, gather tools | 1-2 hours |

| Cutting Ducts | Precise measurements, clean cuts | 2-3 hours |

| Connection | Secure joints, seal connections | 3-4 hours |

Remember, patience and detail are key for a good DIY duct installation. Take your time, check your measurements, and make sure each connection is tight and sealed.

Installing Supply and Return Plenums

Plenums are key parts of your HVAC system. They help distribute air around your home. Knowing how they work and how to install them is important for fixing ducts and making new ones.

These big air storage areas link to your heating and cooling system. They are vital for moving air and controlling temperature. There are two main types of plenums:

- Supply Plenum: Sends cooled or heated air from the HVAC unit

- Return Plenum: Takes air back from rooms for recycling

Plenum Assembly Techniques

Getting ready for plenum installation means being precise and measuring carefully. Here’s what you need to do for air duct fabrication:

- Measure your HVAC system’s size accurately

- Choose the right materials like galvanized steel or aluminum

- Use professional tools to cut panels

- Make sure connections are tight and smooth

Connecting to HVAC Equipment

Connecting the plenum to your HVAC unit is key for good duct repair. Make sure it fits well and is secure. Use special brackets and sealants to stop air leaks.

Proper Sealing Methods

Sealing is important to keep energy in and efficiency up. Use top-notch duct sealants and metallic tape made for HVAC. Focus on joints and any gaps.

Pro Tip: Always wear protective gear and follow manufacturer guidelines during plenum installation.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopBranch Duct Installation and Connections

Installing branch ducts is key to a good HVAC system. They spread air around your home, linking main ducts to rooms. Working with sheet metal ductwork needs precision and planning for best air flow.

For branch ducts to work well, you must know how to connect them. Your flexible duct tips should cover a few important methods:

- Measure branch duct lengths accurately

- Use proper supports for galvanized round pipes

- Ensure tight and sealed connections

- Minimize bends and restrictions in airflow

When dealing with various duct materials, remember these key connection strategies:

| Duct Type | Connection Method | Key Considerations |

|---|---|---|

| Sheet Metal | Slip joints and drive cleats | Require tight sealing with professional-grade sealant |

| Flexible Ducts | Compression rings | Minimize stretching and kinks |

| Transitional Connections | Adapter fittings | Ensure smooth airflow between different duct types |

Don’t forget to support branch ducts in joist spaces. Right support stops sagging and keeps air flow steady. Use metal strapping or special hangers every 4-5 feet to keep ducts straight and secure.

Good, clean connections are vital for your HVAC system’s performance and efficiency.

Sealing and Insulating Ductwork

Your HVAC system works best when ductwork is sealed and insulated right. Good ductwork sealing boosts your home’s energy use and comfort. Experts say it’s key to stop air leaks and get the most from your system.

When you upgrade your HVAC, knowing how to seal ducts is vital. Your ductwork is like your home’s heart for climate control. Any leaks or inefficiencies waste a lot of energy.

Choosing the Right Sealants

Choosing the right sealants depends on your ductwork’s material and where it is. Here are some tips:

- Use mastic sealant for flexible, permanent connections

- Apply metallic foil tape for quick fixes of small gaps

- Go for water-based sealants inside your home

- Choose exterior-grade sealants for ducts outside

Insulation Materials and Application

Insulation keeps your ductwork stable against temperature changes. Here are some options:

- Fiberglass wrap with a protective coating

- Reflective foil insulation

- Foam board for rigid duct parts

- Spray foam for hard spots

Preventing Air Leaks

Air leaks hurt your HVAC’s efficiency a lot. Check duct connections, joints, and seams often. Use a smoke pencil or infrared camera to find leaks during your HVAC upgrade.

Pro tip: Seal ductwork joints with mechanical fasteners before applying sealant for maximum air-tight performance.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopInstalling Registers and Grilles

Installing registers and grilles right is key for good home ductwork and HVAC performance. They help spread air around your home and keep the system running well.

When picking registers, think about a few things:

- Room size and function

- Airflow needs

- Design you like

- How long they last

Before you start, get your areas ready. Registers go between floor joists, not over them. For walls and ceilings, measure and cut openings carefully for a perfect fit.

Here’s how to install them:

- Measure the duct opening size

- Pick the right register size

- Cut openings straight and clean

- Use the right hardware to mount them

- Seal edges to stop air leaks

Return air grilles need extra care. They must be placed right to keep air pressure balanced and support your HVAC system.

Pro Tip: Always ensure proper alignment and secure mounting to maximize airflow efficiency.

By following these steps, you’ll get a top-notch home ductwork replacement. It will make your home more comfortable and energy-efficient.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopSystem Testing and Airflow Verification

After you finish installing your hvac ductwork, it’s important to test the system. This ensures it works well and efficiently. It also helps find any problems early on.

Checking for Leaks

Finding air leaks is key in hvac duct repair. Here are ways to spot issues:

- Visual inspection of duct connections

- Smoke pencil test for air movement

- Pressurization test using specialized equipment

Balancing Airflow

Having balanced airflow means your home stays at a consistent temperature. Use an anemometer to check air speed and volume in each room.

- Measure airflow at each register

- Compare readings against manufacturer specifications

- Adjust dampers to equalize air distribution

Performance Testing

Testing your HVAC system’s performance is crucial. Look at temperature differences, air speed, and energy use.

Accurate testing can help you identify potential improvements in your do it yourself hvac ductwork installation.

If you find big differences during testing, it might be time to get an HVAC expert. They can give a detailed check and suggest changes.

Common DIY Installation Mistakes to Avoid

DIY duct installation can be tough, even for skilled homeowners. Knowing the potential problems in your hvac system retrofit can save you time, money, and stress.

To avoid common mistakes, you need careful planning and attention to detail. Some big errors can really hurt your HVAC system’s performance and efficiency.

- Incorrect Duct Sizing: Choosing ducts that are too small or too large can cut down airflow and system efficiency

- Poor Sealing Techniques: Bad duct sealing causes air leaks and energy waste

- Improper Material Selection: Using the wrong ductwork materials

- Incorrect Register Placement: Blocking vents or placing them badly

When doing DIY duct installation, focus on these key areas. Right measurement, quality materials, and knowing your HVAC system’s needs are crucial for a good install.

Professional-grade sealants and proper insulation can stop many common mistakes. Take time to learn and understand each step before starting your hvac system retrofit.

Careful preparation prevents poor performance in HVAC ductwork installations.

By avoiding these common mistakes, you’ll get a more efficient, effective, and lasting HVAC system. It will give you better comfort and save energy.

Conclusion

Replacing home ductwork needs skill, patience, and attention to detail. Your DIY project can make your home’s heating and cooling better. You now know how to make a strong ventilation system that makes your home more comfortable and saves money.

By following this guide, you can get professional results without the high cost of contractors. Installing it right makes your HVAC system work best. This means cleaner air and lower bills for you.

Don’t forget to keep your ductwork in good shape. Regular checks, cleanings, and fixes will make it last longer. With your new skills, you can handle your home’s air needs well. This will keep your home comfortable and efficient for many years.

Your DIY ductwork project is more than just fixing your home. It shows your technical skills and dedication to a healthier, more comfortable living space. Enjoy the pride of finishing this big project with skill and precision.