Affiliate Disclosure

HVAC Guide Guys is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.

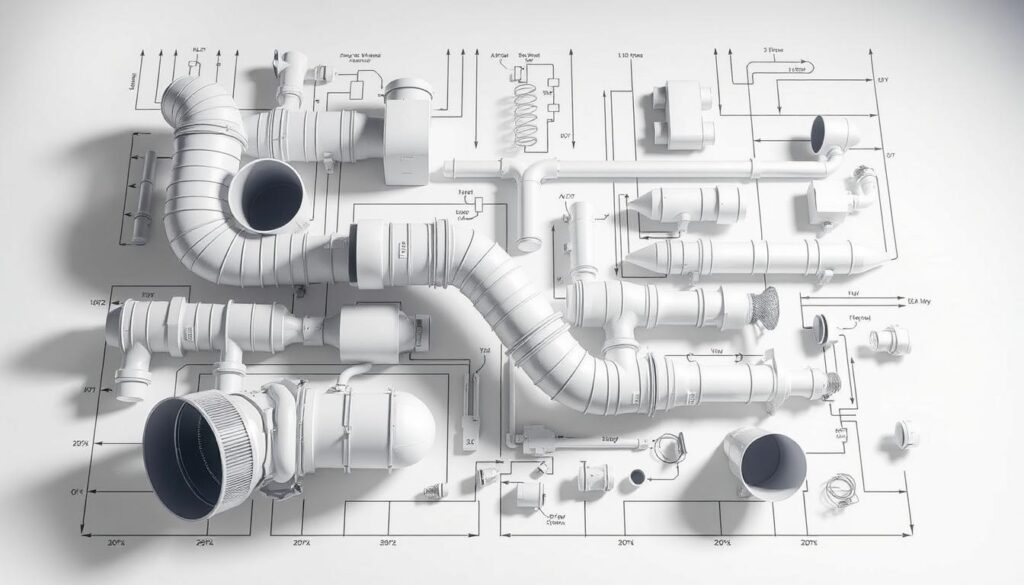

How to Assemble HVAC Ductwork? Ready to cut your home’s heating and cooling costs? Learning to assemble HVAC ductwork can make your home more comfortable and efficient. It can also save you thousands of dollars in professional installation fees.

Ductwork installation might look hard, but with the right help, you can do it. You can learn to install ductwork like a pro. This will let homeowners make their homes more comfortable and energy-efficient.

This guide will cover everything you need to know about ductwork installation. You’ll learn how to pick the right materials and how to connect them correctly. You’ll get the skills to upgrade your HVAC system successfully.

Key Takeaways

- DIY ductwork installation can save up to $2,500 for typical homes

- Proper planning is crucial for successful ductwork assembly

- Understanding system design impacts overall HVAC efficiency

- Essential tools and safety equipment are fundamental to installation

- Precise measurements ensure optimal air distribution

Table of Contents

Essential Tools and Materials for HVAC Ductwork Installation

Getting ready for a DIY ductwork project means you need the right tools. Your HVAC duct connections need precision and safety. This starts with having the right tools.

Basic Sheet Metal Tools for Precision Work

For clean and accurate HVAC duct connections, you need professional-grade sheet metal tools. Your toolkit should include:

- Hand seamers for bending and shaping metal

- Right and left hand snips for cutting sheet metal

- Straight bench snips for precise cuts

- Barfold tool for creating clean metal folds

- Circular saw for larger cutting tasks

Safety Equipment and Protective Gear

Safety is key during DIY ductwork assembly. Protect yourself with these essential items:

- Heavy-duty work gloves

- Safety glasses with side protection

- Dust mask or respirator

- Steel-toed work boots

- Long-sleeve protective clothing

Precision Measuring and Cutting Tools

Accurate measurements are crucial for HVAC duct connections. Invest in high-quality measuring tools such as:

- Retractable tape measure

- Metal ruler

- Angle finder

- Drill with 1/4″ hexhead driver

- Reciprocating saw for complex cuts

Pro tip: Always double-check measurements before cutting to minimize waste and ensure precise DIY ductwork assembly.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopPlanning Your Ductwork Layout and Design

Starting your ductwork project needs careful planning and design. Your HVAC system’s efficiency depends on a well-designed sheet metal duct assembly. This ensures good airflow and saves energy.

- Home square footage and layout

- Room-by-room heating and cooling needs

- Existing HVAC equipment’s capabilities

- Structural constraints and obstacles

Professional HVAC designers suggest doing a detailed load calculation. This helps figure out the right duct size and system needs. Manual J calculations show your home’s thermal characteristics and ventilation needs.

“Proper ductwork design is the foundation of an efficient HVAC system” – HVAC Engineering Professionals

When designing your sheet metal duct assembly, keep these points in mind:

- Map out the best supply register locations

- Plan the return air pathways

- Ensure balanced airflow in all living areas

- Reduce duct length and bends

While you can try DIY duct installation, getting professional help is wise. It helps avoid costly errors and ensures your system works at its best.

How to Assemble HVAC Ductwork: Step-by-Step Process

Assembling HVAC ductwork needs precision and attention to detail. You must know the right techniques and methods for assembly. This ensures air flows well in your space.

Before starting, make sure you have all the materials and tools ready. Preparation is crucial for a smooth process.

Preparing the Installation Area

First, map out your ductwork layout carefully. Important steps include:

- Measuring the space accurately

- Marking supply register locations

- Identifying potential obstructions

- Clearing the installation area

Installing Supply and Return Plenums

Plenums are key in your hvac system. They spread air from the main unit to different ductwork branches.

- Position the main plenum near the air handler

- Secure connections using ductwork fabrication techniques

- Make sure all connections are airtight

“Precision in plenum installation determines the overall efficiency of your HVAC system.” – HVAC Engineering Professionals

Connecting Main Trunk Lines

Connecting trunk lines needs careful alignment and secure fastening. Use S-cleats and drives for strong, leak-free joints. Focus on:

- Maintaining proper alignment

- Using the right fastening techniques

- Checking for smooth air flow

Pro tip: Always double-check your connections to prevent air leakage and ensure maximum system efficiency.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopProper Ductwork Support and Mounting Techniques

When you install HVAC ductwork, it’s key to support it right. This keeps your system running well and avoids damage. Your steps for ductwork installation should include strong mounting methods for lasting stability and performance.

Choosing the right support method is very important for your HVAC duct connections. Experts say there are a few main ways to secure ductwork well:

- Use adjustable steel support brackets for maximum flexibility

- Maintain consistent support spacing to prevent sagging

- Select appropriate fasteners designed for sheet metal connections

- Consider both horizontal and vertical mounting requirements

For horizontal ductwork, experts suggest using support brackets every 4 to 5 feet. Vertical duct runs need more support, usually at each floor level and near big changes in direction.

When mounting your ductwork, focus on these important points:

- Choose 1-inch galvanized zip screws specifically designed for sheet metal

- Ensure each connection uses at least three screws

- Verify that screws are not necessarily evenly spaced but strategically placed

- Check that brackets provide stable, vibration-free support

Proper ductwork support does more than just prevent collapse. It also keeps air flow and system efficiency at their best. Spend time on careful mounting to make sure your HVAC system works its best.

Supply and Return Air Connections

Creating effective hvac duct connections is key for a well-working system. Your HVAC system’s performance depends on precise air connection techniques. These ensure proper airflow and temperature control in your home.

Proper air connection methods involve several critical steps. Homeowners and professional installers must understand these to keep the system efficient.

Boot Installation Techniques

Boot installation needs careful attention. Follow these key steps:

- Measure the opening precisely before cutting

- Ensure tight seal around the boot perimeter

- Use appropriate fasteners for secure mounting

- Apply mastic sealant to prevent air leakage

Register Placement Guidelines

Strategic register placement is key for better air distribution and comfort. Consider these placement recommendations:

| Room Type | Recommended Register Location |

|---|---|

| Living Room | Near exterior walls, away from furniture |

| Bedroom | Under windows or on side walls |

| Kitchen | Ceiling or high wall locations |

Return Air System Setup

Your return air system is crucial for indoor air quality. Proper panning and sealing techniques ensure efficient air circulation and system performance.

When installing return air connections, use flat metal panning to direct airflow. Seal all joints meticulously to prevent air leakage and maintain system efficiency.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopSealing and Insulating Ductwork Properly

Sealing your ductwork right is key to a good HVAC system. Leaks can cut your system’s efficiency by 20%, wasting energy and raising bills. Knowing how to seal properly keeps your air clean and boosts system performance.

Focus on these areas when sealing your HVAC ductwork:

- Joints and connections between duct sections

- Seams and gaps in ductwork

- Connections to registers and vents

- Plenum and trunk line intersections

For effective sealing, use these materials:

| Sealing Material | Best Used For | Durability |

|---|---|---|

| Foil Tape | Permanent connections | High |

| Mastic Sealant | Flexible connections | Medium to High |

| Silicone Caulk | Small gaps and joints | Medium |

Clean the surfaces well before applying sealants. Make sure to spread the sealant evenly. Check all connections carefully to ensure a tight seal against air leaks.

“A well-sealed duct system can improve your HVAC efficiency by up to 30%” – HVAC Professionals Association

Don’t forget about hidden ducts in walls, attics, and crawl spaces. These spots are often missed but are vital for your system’s health.

Common Installation Mistakes to Avoid

When you’re doing diy ductwork assembly, it’s key to avoid big mistakes. These errors can cost you time, money, and make your HVAC system less efficient. Knowing the common pitfalls is crucial for a job well done.

For a successful ductwork installation, you need precision and the right knowledge. Here are the top mistakes DIY folks should avoid:

Proper Bend Radius Requirements

Flexible ducts need careful handling when bending. Follow these important tips:

- Keep bends at least one full duct diameter wide

- Avoid sharp turns that block airflow

- Make bends smooth and gradual to reduce resistance

Support Spacing Guidelines

Not enough support can cause sagging and lower system efficiency. Your ductwork techniques should include:

- Supports every 4-5 feet for horizontal runs

- Use adjustable hanging straps

- Prevent stretching or compressing too much

Air Flow Considerations

Good air flow is essential for any HVAC system. Consider these points:

- Make sure ducts are the right size for your space

- Reduce unnecessary bends and transitions

- Check for any air flow blockages

Pro tip: Always measure twice and cut once during your diy ductwork assembly to prevent costly mistakes.

Explore Our HVAC Shop

Looking for top-rated HVAC tools, parts, and accessories? Visit our shop and find the perfect solution for your needs.

Visit the ShopMaintenance and Quality Control Checks

Keeping your HVAC system in good shape is key. Regular checks help avoid problems and keep your ductwork working well.

It’s important to keep your ductwork clean. This is especially true during and after building work. You need to make sure your system stays clean and works right.

- Inspect duct boots and seals regularly

- Check for air leaks in connection points

- Verify insulation integrity

- Ensure proper support for ductwork sections

When you’re doing quality control, focus on these important areas:

- Seal Integrity: Look for any gaps or potential air leakage points

- Structural Support: Confirm all mounting hardware remains secure

- Cleanliness: Inspect for dust, debris, or potential contaminants

Remember, your HVAC system needs special care. Floor ducts need extra protection during building work. Also, be careful with flexible ductwork. It can damage fire-rated assemblies if not installed correctly.

Proactive maintenance can extend the life of your HVAC system and prevent costly repairs down the line.

By following a regular maintenance plan, you can spot problems early. This keeps your ductwork in great shape. It ensures your space gets the air it needs efficiently.

Conclusion

Assembling HVAC ductwork needs careful planning and precision. By following this guide, you can install ductwork in your home. This improves air circulation and energy efficiency.

It’s not just about connecting metal pieces. It’s about making a system that moves air well in your home. Proper installation can save you money and improve air quality.

Always keep safety and precision in mind. If you face tough challenges, get help from HVAC experts. They can guide you through complex steps and ensure your system works great.

Understanding how to assemble ductwork is key to a comfortable and efficient home. Take your time, follow the manufacturer’s instructions, and be careful with each step.